Page 420 - Industrial Wastewater Treatment, Recycling and Reuse

P. 420

392 Industrial Wastewater Treatment, Recycling, and Reuse

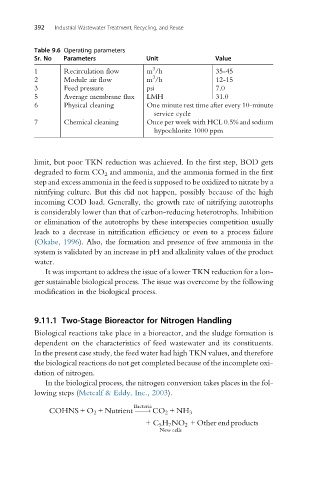

Table 9.6 Operating parameters

Sr. No Parameters Unit Value

3

1 Recirculation flow m /h 35-45

3

2 Module air flow m /h 12-15

3 Feed pressure psi 7.0

5 Average membrane flux LMH 31.0

6 Physical cleaning One minute rest time after every 10-minute

service cycle

7 Chemical cleaning Once per week with HCL 0.5% and sodium

hypochlorite 1000 ppm

limit, but poor TKN reduction was achieved. In the first step, BOD gets

degraded to form CO 2 and ammonia, and the ammonia formed in the first

step and excess ammonia in the feed is supposed to be oxidized to nitrate by a

nitrifying culture. But this did not happen, possibly because of the high

incoming COD load. Generally, the growth rate of nitrifying autotrophs

is considerably lower than that of carbon-reducing heterotrophs. Inhibition

or elimination of the autotrophs by these interspecies competition usually

leads to a decrease in nitrification efficiency or even to a process failure

(Okabe, 1996). Also, the formation and presence of free ammonia in the

system is validated by an increase in pH and alkalinity values of the product

water.

It was important to address the issue of a lower TKN reduction for a lon-

ger sustainable biological process. The issue was overcome by the following

modification in the biological process.

9.11.1 Two-Stage Bioreactor for Nitrogen Handling

Biological reactions take place in a bioreactor, and the sludge formation is

dependent on the characteristics of feed wastewater and its constituents.

In the present case study, the feed water had high TKN values, and therefore

the biological reactions do not get completed because of the incomplete oxi-

dation of nitrogen.

In the biological process, the nitrogen conversion takes places in the fol-

lowing steps (Metcalf & Eddy, Inc., 2003).

Bacteria

COHNS + O 2 + Nutrient ! CO 2 +NH 3

+C 5 H 7 NO 2 + Other end products

New cells