Page 421 - Industrial Wastewater Treatment, Recycling and Reuse

P. 421

An Introduction to Biological Treatment and Membrane Filtration 393

+

+

2NH 4 +3O 2 ! 2NO 2 +4H +2H 2 O

2NO 2 +O 2 ! 2NO 3

To address the nitrogen problem, a two-stage bioreactor method was

applied. The first tank was used as a pre-aeration tank in which feed

wastewater was added and aerated for 8–10 h. The overflow from this

tank was fed into another biological tank connected with the membrane

system, which was again aerated maintaining a predetermined HRT. In

the first tank 70–75% COD reduction took place, which reduced the

COD loading for the second tank. The second tank experienced less feed

COD to be degraded and high ammonia, which is a favorable environ-

ment for the nitrifying culture to develop and complete the nitrification

process. Nitrification was indicated by reduction in TKN, pH, and the

alkalinityvaluesof theproduct.Oncesludgewasacclimated tothecon-

ditions, the bioreactor started showing consistent reduction in pH and

alkalinity values.

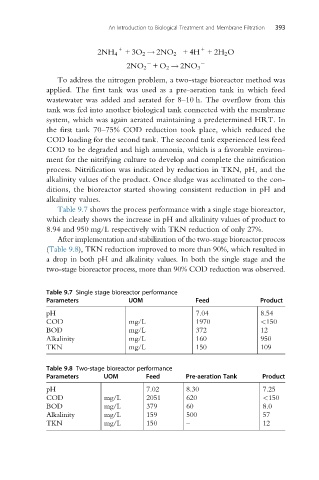

Table 9.7 shows the process performance with a single stage bioreactor,

which clearly shows the increase in pH and alkalinity values of product to

8.94 and 950 mg/L respectively with TKN reduction of only 27%.

After implementation and stabilization of the two-stage bioreactor process

(Table 9.8), TKN reduction improved to more than 90%, which resulted in

a drop in both pH and alkalinity values. In both the single stage and the

two-stage bioreactor process, more than 90% COD reduction was observed.

Table 9.7 Single stage bioreactor performance

Parameters UOM Feed Product

pH 7.04 8.54

COD mg/L 1970 <150

BOD mg/L 372 12

Alkalinity mg/L 160 950

TKN mg/L 150 109

Table 9.8 Two-stage bioreactor performance

Parameters UOM Feed Pre-aeration Tank Product

pH 7.02 8.30 7.25

COD mg/L 2051 620 <150

BOD mg/L 379 60 8.0

Alkalinity mg/L 159 500 57

TKN mg/L 150 – 12