Page 423 - Industrial Wastewater Treatment, Recycling and Reuse

P. 423

An Introduction to Biological Treatment and Membrane Filtration 395

%Rejection

Feed COD

7000

100

6000 90

Feed COD(mg/L) 4000 70 % COD rejection

80

5000

60

50

3000

40

2000

30

20

1000

10

0 0

0 50 100 150 200 250 300 350

Number of Days of Operation

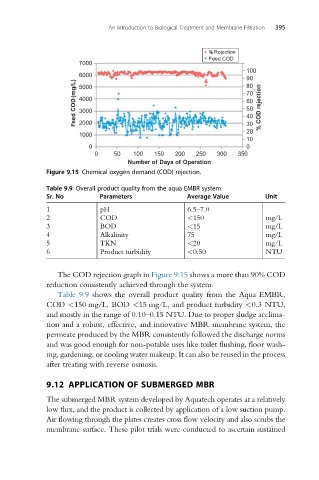

Figure 9.15 Chemical oxygen demand (COD) rejection.

Table 9.9 Overall product quality from the aqua EMBR system

Sr. No Parameters Average Value Unit

1 pH 6.5–7.0

2 COD <150 mg/L

3 BOD <15 mg/L

4 Alkalinity 75 mg/L

5 TKN <20 mg/L

6 Product turbidity <0.50 NTU

The COD rejection graph in Figure 9.15 shows a more than 90% COD

reduction consistently achieved through the system.

Table 9.9 shows the overall product quality from the Aqua EMBR,

COD <150 mg/L, BOD <15 mg/L, and product turbidity <0.3 NTU,

and mostly in the range of 0.10–0.15 NTU. Due to proper sludge acclima-

tion and a robust, effective, and innovative MBR membrane system, the

permeate produced by the MBR consistently followed the discharge norms

and was good enough for non-potable uses like toilet flushing, floor wash-

ing, gardening, or cooling water makeup. It can also be reused in the process

after treating with reverse osmosis.

9.12 APPLICATION OF SUBMERGED MBR

The submerged MBR system developed by Aquatech operates at a relatively

low flux, and the product is collected by application of a low suction pump.

Air flowing through the plates creates cross flow velocity and also scrubs the

membrane surface. These pilot trials were conducted to ascertain sustained