Page 447 - Industrial Wastewater Treatment, Recycling and Reuse

P. 447

418 Industrial Wastewater Treatment, Recycling, and Reuse

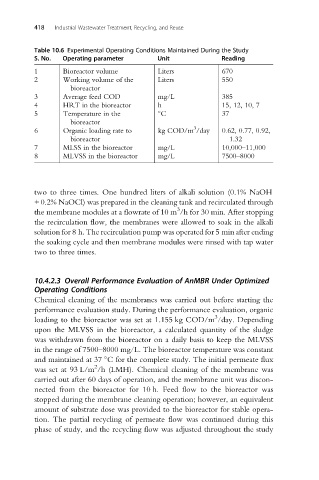

Table 10.6 Experimental Operating Conditions Maintained During the Study

S. No. Operating parameter Unit Reading

1 Bioreactor volume Liters 670

2 Working volume of the Liters 550

bioreactor

3 Average feed COD mg/L 385

4 HRT in the bioreactor h 15, 12, 10, 7

5 Temperature in the C 37

bioreactor

3

6 Organic loading rate to kg COD/m /day 0.62, 0.77, 0.92,

bioreactor 1.32

7 MLSS in the bioreactor mg/L 10,000–11,000

8 MLVSS in the bioreactor mg/L 7500–8000

two to three times. One hundred liters of alkali solution (0.1% NaOH

+0.2% NaOCl) was prepared in the cleaning tank and recirculated through

3

the membrane modules at a flowrate of 10 m /h for 30 min. After stopping

the recirculation flow, the membranes were allowed to soak in the alkali

solution for 8 h. The recirculation pump was operated for 5 min after ending

the soaking cycle and then membrane modules were rinsed with tap water

two to three times.

10.4.2.3 Overall Performance Evaluation of AnMBR Under Optimized

Operating Conditions

Chemical cleaning of the membranes was carried out before starting the

performance evaluation study. During the performance evaluation, organic

3

loading to the bioreactor was set at 1.155 kg COD/m /day. Depending

upon the MLVSS in the bioreactor, a calculated quantity of the sludge

was withdrawn from the bioreactor on a daily basis to keep the MLVSS

in the range of 7500–8000 mg/L. The bioreactor temperature was constant

and maintained at 37 C for the complete study. The initial permeate flux

2

was set at 93 L/m /h (LMH). Chemical cleaning of the membrane was

carried out after 60 days of operation, and the membrane unit was discon-

nected from the bioreactor for 10 h. Feed flow to the bioreactor was

stopped during the membrane cleaning operation; however, an equivalent

amount of substrate dose was provided to the bioreactor for stable opera-

tion. The partial recycling of permeate flow was continued during this

phase of study, and the recycling flow was adjusted throughout the study