Page 102 - Instrumentation Reference Book 3E

P. 102

Methods providing full-range level measurement 87

sophisticated form that uses a pre-wound

“Neg’ator” (also called “Tensator”) spring torque

Scale graduated in mm motor that has its torque characteristic tailored

to vary as more tape is to be supported during

windout.

The production costs of precision mechanical

systems can make them less attractive than elec-

tronic equivalents but such systems do have

the advantages that no electrical power supply

is needed. Previously, another advantage of

mechanical level systems was the fact that a wider

range of plant operators easily understood them.

This is no longer necessarily the case. It is com-

monly now recommended that non-contacting or

non-invasive level measurements be the measure-

ments of first choice where possible.

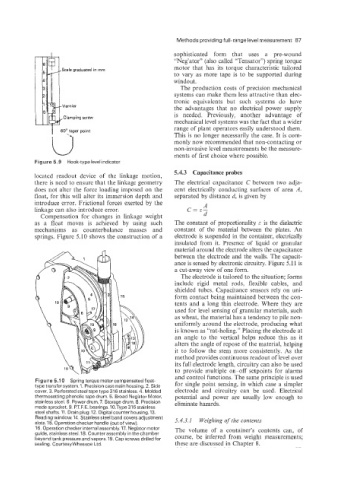

Figure 5.9 Hook-type level indicator

5.4.3 Capacitance probes

located readout device of the linkage motion,

there is need to ensure that the linkage geometry The electrical capacitance C between two adja-

does not alter the force loading imposed on the cent electrically conducting surfaces of area A,

float, for this will alter its immersion depth and separated by distance d, is given by

introduce error. Frictional forces exerted by the A

linkage can also introduce error. C=E-

Compensation for changes in linkage weight d

as a float moves is achieved by using such The constant of proportionality E is the dielectric

mechanisms as counterbalance masses and constant of the material between the plates. An

springs. Figure 5.10 shows the construction of a electrode is suspended in the container, electrically

insulated from it. Presence of liquid or granular

material around the electrode alters the capacitance

between the electrode and the walls. The capacit-

ance is sensed by electronic circuitry. Figure 5.11 is

a cut-away view of one form.

The electrode is tailored to the situation; forms

include rigid metal rods, flexible cables, and

shielded tubes. Capacitance sensors rely on uni-

form contact being maintained between the con-

tents and a long thin electrode. Where they are

used for level sensing of granular materials, such

as wheat, the material has a tendency to pile non-

uniformly around the electrode, producing what

is known as “rat-holing.’’ Placing the electrode at

an angle to the vertical helps reduce this as it

alters the angle of repose of the material, helping

it to follow the stem more consistently. As the

method provides continuous readout of level over

its full electrode length, circuitry can also be used

to provide multiple on-off setpoints for alarms

and control functions. The same principle is used

Figure 5.1 0 Spring torque motor compensated float- for single point sensing, in which case a simpler

type transfer system. 1. Precision cast main housing. 2. Side

cover. 3. Perforated steel tape type 316 stainless. 4. Molded electrode and circuitry can be used. Electrical

thermosetting phenolic tape drum. 5. Broad Neg’ator Motor, potential and power are usually low enough to

stainless steel. 6. Power drum. 7. Storage drum. 8. Precision eliminate hazards.

made sprocket. 9. P.T F. E. bearings. 10.Type 316 stainless

steel shafts. 11. Drain plug. 12. Digital counter housing. 13.

Reading window. 14. Stainless steel band covers adjustment 5.4.3.1 Weighing of the contents

slots. 15. Operation checker handle (out of view).

16. Operation checker internal assembly. 17. Neg’ator motor The volume of a container’s contents can, of

guide, stainless steel. 18. Counter assembly in the chamber

beyond tank pressure and vapors. 19. Cap screws drilled for course, be inferred from weight measurements;

sealing. CourtesyWhessoe Ltd. these are discussed in Chapter 8.