Page 104 - Instrumentation Reference Book 3E

P. 104

Methods providing full-range level measurement 89

city of the waves is known, the distance may then

be calculated.

Many variations exist upon this basic theme.

The choice of radiation, use from above or from

below, and of frequency depend much upon the

material and the accuracy sought.

Although pulses are sent, the repetition rate is

fast enough for the output to appear continuous.

The method can be made suitable for use in

hazardous regions.

5.4.7 Force or position balance

In these methods a short-range sensor, such as a

float resting in the surface or a surface sensor of

an electronic nature, is used to provide automatic

control signals that take in, or let out, cable or

wire so that the sensor is held at the same position

relative to the surface. Figure 5.13 gives the

arrangement of one such system that makes use

Figure 6.32 Assembly view of Fisher torque tube unit.

Courtesy, GEC Elliot ConrrolValves Ltd.

granular materials may not fulfill this require-

ment) then pressure acting upon a given area at

the bottom of a tank is proportional only to the

density of the fluid and the head of pressure. In

most cases density can be assumed to be uniform,

thereby allowing a pressure sensor, placed on the

bottom, to be used as a measure of tank level.

Pressure gauges are described in Chapter 9.

Lying in the same class are purge methods. The

pressure needed to discharge gas or liquid from a

nozzle placed at the bottom of the tank depends

upon the head of liquid above and its density.

Bubblers, as these are called, are simple to

arrange and give readout as a pressure-gauge

reading that can be read directly or transduced

into a more suitable form of signal.

Obviously bubblers do not work in granular

materials. The addition of small quantities of

liquid or gas must not significantly affect the

contents of the tank.

5.4.6 Microwave and ultrasonic, time-transit

methods

A source of coherent radiation, such as ultra-

sound or microwaves, can be used to measure

the distance from the surface to the top of the

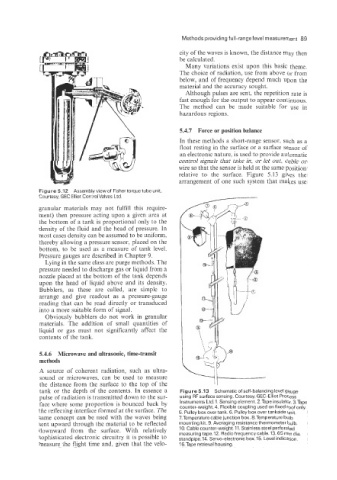

tank or the depth of the contents. In essence a Figure 5.13 Schematic of self-balancing level gauge

pulse of radiation is transmitted down to the sur- using RF surface sensing. Courtesy, GEC-Elliot Process

Instruments Ltd.1. Sensing element. 2.Tape insulator. 3.Tape

face where some proportion is bounced back by counter-weight. 4. Flexible coupling used on fixed roof only.

the reflecting interface formed at the surface. The 5. Pulley box over tank. 6. Pulley box over tankside unit.

same concept can be used with the waves being 7,Temperature cable junction box. 8,Temperature bulb

sent upward through the material to be reflected mounting kit. 9. Averaging resistance thermometer bulb.

downward from the surface. With relatively 10. Cable counter-weight. 11. Stainless steel perforated

sophisticated electronic circuitry it is possible to measuring tape. 12. Radio frequency cable. 13.65 mm dia.

standpipe. 14. Servo-electronic box. 15. Level indication.

measure the flight time and, given that the velo- 16.Tape retrieval housing.