Page 98 - Instrumentation Reference Book 3E

P. 98

Calibration of level-measuring systems 83

Granular materials will not generally flow to also exists due to the actual depth to which the

form a flat surface as do liquids. The angle of float sinks to provide its necessary buoyancy

repose of the material and the form of input and force. This varies with material density which

output porting will give rise to error in volume often varies with temperature.

calculations if the actual geometry is not allowed A second class of errors arise due to tempera-

for in use of a single point sensor. ture and, to a lesser extent, pressure changes to

Turbulence occurring at the sensor, caused by the contents. Where the required measurement is

material flow in the container or by vibrations a determination of the volume or mass of the con-

acting on ithe container, may also be a source of tents, use is made of level as an indirect step toward

error. It is common practice to mount a mechan- that need. All materials change volume with chang-

ical level sensor in some form of integrating ing temperature. It may therefore be necessary to

chamber that smooths out transient dynamic vari- provide temperature measurements so that level

ations. A common method is the use of a stilling outputs can be corrected.

pipe or well that is allowed to fill to the same level For some forms of level sensor external still

as the contents via small holes-see Figures 5.3 tubes should be situated to retain the same tem-

and 5.4. The time rate responses of such still perature as that of the tank because localized

tubes. however. become important in fast-moving heating, or cooling, can cause the contents of

systems as they can introduce phase-shift and the still tube to have a different density from that

amplitude attenuation. existing in the tank. Methods that are based upon

Changes of the mass of floats, due to sediment use of buoyancy chambers, which produce a meas-

build-up or corrosion. will alter the depth of urement force rather than following the surface.

immersion of float sensors. A systematic error will produce force outputs that vary with tem-

perature due to altered buoyancy upthrust as the

density of the fluid changes.

Floats are generally made from waterproofed

Rodding

Gaugehead out paints cork, stainless steel, copper, and plastic materials.

The material used may need to be corrosion-resist-

ant. Where the contents are particularly corro-

sive, or otherwise inhospitable to the components

of the sensing systems, it is preferable to reduce.

to the absolute minimum. the number of sub-

system parts that are actually immersed in the

contents.

Considerable use is made of magnetic coupling

between the guided float and the follower. Figure

5.5 shows one such arrangement.

Nuclear level gauging offers the distinct advant-

External nil1 pipe with age (see Figure 5.6) that no part of the level-

removable flanges detecting system need be inside the container. It is

at each 0nd

discussed further in Part 3.

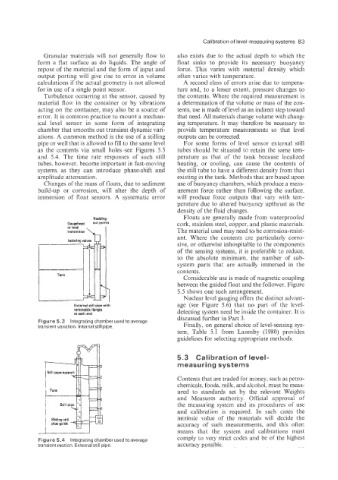

Figure 5.3 Integrating chamber used to average

transient variation. internal still pipe. Finally, on general choice of level-sensing sys-

tem, Table 5.1 from Lazenby (1980) provides

guidelines for selecting appropriate methods.

5.3 Calibration of level-

measuring systems

Contents that are traded for money, such as petro-

chemicals, foods, milk, and alcohol, must be meas-

ured to standards set by the relevant Weights

and Measures authority. Official approval of

the measuring system and its procedures of use

and calibration is required. In such cases the

intrinsic value of the materials wili decide the

accuracy of such measurements, and this often

means that the system and calibrations must

Figure 5.4 Integrating chamber used to average comply to very strict codes and be of the highest

transient motion. External still pipe. accuracy possible.