Page 226 - Instrumentation Reference Book 3E

P. 226

210 Microprocessor-based and intelligent transmitters

protectors.

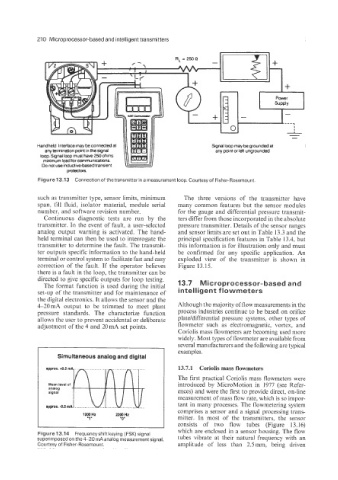

Figure 13.13 Connection of the transmitter in a measurement loop. Courtesy of Fisher-Rosemount

such as transmitter type, sensor limits, minimum The three versions of the transmitter have

span, fill fluid, isolator material, module serial many common features but the sensor modules

number, and software revision number. for the gauge and differential pressure transmit-

Continuous diagnostic tests are run by the ters differ from those incorporated in the absolute

transmitter. In the event of fault, a user-selected pressure transmitter. Details of the sensor ranges

analog output warning is activated. The hand- and sensor limits are set out in Table 13.3 and the

held terminal can then be used to interrogate the principal specification features in Table 13.4, but

transmitter to determine the fault. The transmit- this information is for illustration only and must

ter outputs specific information to the hand-held be confirmed for any specific application. An

terminal or control system to facilitate fast and easy exploded view of the transmitter is shown in

correction of the fault. If the operator believes Figure 13.15.

there is a fault in the loop, the transmitter can be

directed to give specific outputs for loop testing. 13.7 Microprocessor-based and

The format function is used during the initial

set-up of the transmitter and for maintenance of intelligent flowmeters

the digital electronics. It allows the sensor and the

4-20mA output to be trimmed to meet plant Although the majority of flow measurements in the

pressure standards. The characterize function process industries continue to be based on orifice

allows the user to prevent accidental or deliberate plate/differential pressure systems, other types of

adjustment of the 4 and 20mA set points. flowmeter such as electromagnetic, vortex, and

Coriolis mass flowmeters are becoming used more

widely. Most types of flowmeter are available from

several manufacturers and the following are typical

I

Simultaneous analog and digital examples.

approx. +OS mA 13.7.1 Coriolis mass flowmeters

The first practical Coriolis mass flowmeters were

introduced by MicroMotion in 1977 (see Refer-

ences) and were the first to provide direct, on-line

measurement of mass flow rate, which is so impor-

______

appror.Q.5mA[ ........... u..J !.!. tant in many processes. The flowmetering system

comprises a sensor and a signal processing trans-

1203 Hr 2200 Hr I mitter. In most of the transmitters, the sensor

'1 " '0' consists of two flow tubes (Figure 13.16)

which are enclosed in a sensor housing. The flow

Figure 13.14 Frequencyshift keying (FSK) signal

superimposed on the 4-20 mA analog measurement signal. tubes vibrate at their natural frequency with an

Courtesy of Fisher-Rosemount. amplitude of less than 2.5 mm, being driven