Page 228 - Instrumentation Reference Book 3E

P. 228

212 Microprocessor-based and intelligent transmitters

Table 13.3 Range limits for the sensor modules for the differential, gauge, and absolute pressure transmitters

Sensor Model 3501 CD differential pressure Model 3501 CG gauge presswe Model 3501A absolute pressure

code transmitter transmitter transmitter

Minimum Maximum Minimum Maximurn Minimum Maximum

0 NA NA NA NA 1.15kPa 34.6 kPa

1 210Pa 6220 Pa NA NA 6.89 kPa 207 kPa

2 2.07 kPa 62.2 kPa 2.07 kPa 62.2 kPa 34.5 kPa 1.034MPa

3 8.28 kPa 248 kPa 8.28 kPa 248 kPa 186kPa 5.51 MPa

4 69.0 kPa 2070 kPa 69.0 kPa 2070 kPa 913kPa 27.6 MPa

5 460 kPa 13.8 MPa 460 kPa 13.8 MPa NA NA

NA: not available.

Table 13.4 Outline performance specifications of the 3501C series of transmitters

Service Liquid or gas

output Two-wire &20mA d.c. with the digital value of the

process variable superimposed

Power supply 10.5-55V d.c.

Temperature limits Process: -40°C to +llO”C

Ambient: -40°C to +85”C

Damping Adjustable from 0 to 16 s

Accuracy f0.075% of spans for spans from 1:l to 1O:l of URL

Stability Range 2 & 3: *0.1% of URL for 12 months

Range 4 & 5: +0.2% of URL for 12 months

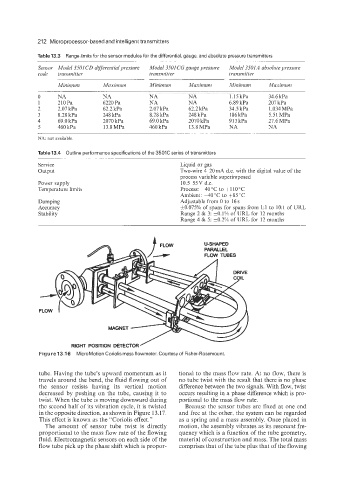

RIGHT POSITION DETECTOR ’

Figure 13.1 6 MicroMotion Coriolis mass flowmeter. Courtesyof Fisher-Rosemount.

tube. Having the tube’s upward momentum as it tional to the mass flow rate. At no flow, there is

travels around the bend, the fluid flowing out of no tube twist with the result that there is no phase

the sensor resists having its vertical motion difference between the two signals. With flow, twist

decreased by pushing on the tube, causing it to occurs resulting in a phase difference which is pro-

twist. When the tube is moving downward during portional to the mass flow rate.

the second half of its vibration cycle, it is twisted Because the sensor tubes are fixed at one end

in the opposite direction, as shown in Figure 13.17. and free at the other, the system can be regarded

This effect is known as the “Coriolis effect.” as a spring and a mass assembly. Once placed in

The amount of sensor tube twist is directly motion, the assembly vibrates as its resonant fre-

proportional to the mass flow rate of the flowing quency which is a function of the tube geometry,

fluid. Electromagnetic sensors on each side of the material of construction and mass. The total mass

flow tube pick up the phase shift which is propor- comprises that of the tube plus that of the flowing