Page 387 - Instrumentation Reference Book 3E

P. 387

370 Chemical analysis: electrochemical techniques

assembly is in the measured solution. Immersion Electrode assemblies should be designed so

depths up to 3 m are available. that the electrodes can be kept wet when not in

use. It is often possible to arrange for the easy

removal of the assembly from the process vessel

so that it can be immersed in a bucket filled with

process liquid, water, or buffer solution during

shutdown.

The design of the assembly is often modified to

suit the use. For example, in measuring the pH of

pulp in a paper beater the electrodes and resist-

ance bulb are mounted side by side in a straight

line and then inclined downstream at about 45 "C

from the vertical so that they present no pockets

to collect pulp and are self-cleaning.

When the assembly is immersed in a tank, care

must be taken in the siting to ensure the instru-

ment is measuring the properties of a representa-

tive sample; adequate mixing of the process

material is essential. Sometimes it is more con-

rference element

venient to circulate the contents of a tank through

a flow type of assembly and then return the liquid

to the tank.

The main cause of trouble in electrode assem-

blies is the fouling of the electrodes. In order to

reduce this, two forms of self-cleaning are avail-

able, and the choice of method is dependent on

the application. Where the main cause of trouble

IC is deposits on the glass, electrode and mechanical

cleaning is required; this may be achieved by the

uY cleaning attachment shown on a dip system in

Direction of flow Figure 17.28. The pneumatically driven rubber

membrane wipes the electrode. providing a sim-

(C)

ple, reliable cleaning action. It is driven by com-

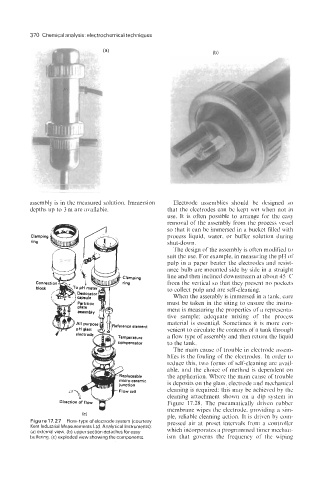

Figure 17.27 Flow-type of electrode system (courtesy pressed air at preset intervals from a controller

Kent Industrial Measurements Ltd. Analytical Instruments):

(a) external view, (b) upper section detaches for easy which incorporates a programmed timer mechan-

buffering, (c) exploded view showing the components. ism that governs the frequency of the wiping