Page 414 - Instrumentation Reference Book 3E

P. 414

Process chromatography 397

sequence and to control the apparatus, and a

display or data-processing device to record the

results of the analyses.

18.4.1 Sampling system

The sampling system must present a homo-

geneous and representative sample of the gas or

liquid to be analyzed to the gas chromatograph.

In process chromatography a continuous stream

of the sample is taken, usually by means of a fast

bypass loop, and treated as necessary, for example,

by drying., filtering, or adjustment of temperature

or pressure. Discrete volumes of the treated sam-

ple stream are periodically injected into the car- fa1 Fill

rier gas stream of the chromatograph by means of

a gas (or liquid) sampling valve. The chromato-

graph is normally supplied with the sample from

the point or points to be monitored by use of

permanently installed sampling lines. However,

where the frequency of analysis does not justify

the installation of special lines, samples may be

collected in suitable containers for subsequent

analysis. Gas samples may be collected under

pressure in metal (usually stainless steel) cylinders

or at atmospheric pressure in gas pipettes, gas

sampling syringes, or plastic bags. For analysis

of gases at very low concentrations such as the

determination of pollutants in ambient air, the

pre-column or adsorption tube concentration

technique is often used. The sample is drawn or lb) Inject

allowed to diffuse through a tube containing a

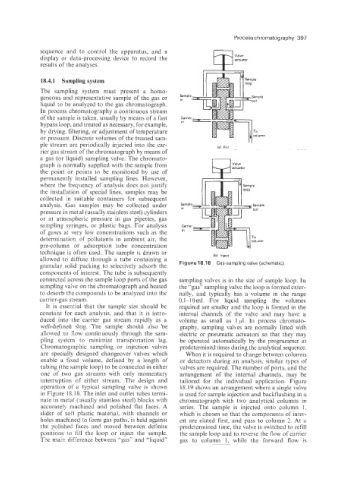

granular solid packing to selectively adsorb the Figure 18.1 8 Gas-sampling valve (schematic)

components of interest. The tube is subsequently

connected across the sample loop ports of the gas sampling valves is in the size of sample loop. In

sampling valve on the chromatograph and heated the “gas” sampling valve the loop is formed exter-

to desorb the compounds to be analyzed into the nally, and typically has a volume in the range

carrier-gas stream. 0.1-10 ml. For liquid sampling the volumes

It is essential that the sample size should be required are smaller and the loop is formed in the

constant for each analysis, and that it is intro- internal channels of the valve and may have a

duced into the carrier gas stream rapidly as a volume as small as 1 pl. In process chromato-

well-defined slug. The sample should also be graphy, sampling valves are normally fitted with

allowed to flow continuously through the sam- electric or pneumatic actuators so that they may

pling system to minimize transportation lag. be operated automatically by the programer at

Chromatographic sampling or injection valves predetermined times during the analytical sequence.

are specially designed changeover valves which When it is required to change between columns

enable a fixed volume, defined by a length of or detectors during an analysis, similar types of

tubing (the sample loop) to be connected in either valves are required. The number of ports, and the

one of two gas streams with only momentary arrangement of the internal channels, may be

interruption of either stream. The design and tailored for the individuai application. Figure

operation of a typical sampling valve is shown 18.19 shows an arrangement where a single valve

in Figure 18.18. The inlet and outlet tubes termi- is used for sample injection and backflushing in a

nate in metal (usually stainless steel) blocks with chromatograph with two analytical columns in

accurately machined and polished flat faces. A series. The sample is injected onto column 1.

slider of soft plastic material, with channels or which is chosen so that the components of inter-

holes machined to form gas paths, is held against est are eluted first, and pass to column 2. At a

the polished faces and moved between definite predetermined time, the valve is switched to refill

positions to fill the loop or inject the sample. the sample loop and to reverse the flow of carrier

The main difference between ”gas” and “liquid” gas to column 1, while the forward flow is