Page 416 - Instrumentation Reference Book 3E

P. 416

Process chromatography 399

Column

Detector

E~~~~~~~~ 1

~ Explosion proof

, Bulb ,snubber fine temp. control

___

indicator Press. reg.

0.34 - 4 bar g

Analvret base Analyzer housing Casting (temp. control)

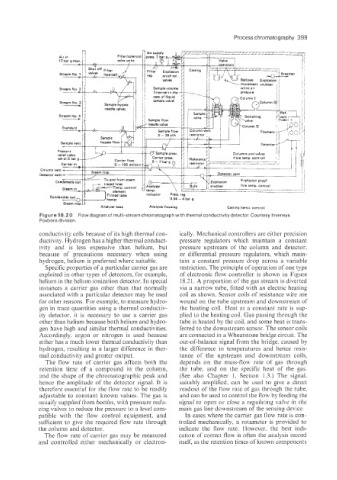

Figure 18.280 Flow diagram of multi-stream chromatograph with thermal conductivitydetector. Courtesy lnvensys

Foxboro division.

conductivity cells because of its high thermal con- ically. Mechanical controllers are either precision

ductivity. Hydrogen has a higher thermal conduct- pressure regulators which maintain a constant

ivity and. is less expensive than helium, but pressure upstream of the column and detector,

because of precautions necessary when using or differential pressure regulators, which main-

hydrogen, helium is preferred where suitable. tain a constant pressure drop across a variable

Specific properties of a particular carrier gas are restriction. The principle of operation of one type

exploited in other types of detectors, for example, of electronic flow controller is shown in Figure

helium in the helium ionization detector. In special 18.21. A proportion of the gas stream is diverted

instances a carrier gas other than that normally via a narrow tube, fitted with an electric heating

associated with a particular detector may be used coil as shown. Sensor coils of resistance wire are

for other reasons. For example, to measure hydro- wound on the tube upstream and downstream of

gen in trace quantities using a thermal conductiv- the heating coil. Heat at a constant rate is sup-

ity detector, it is necessary to use a carrier gas plied to the heating coil. Cas passing through the

other than helium because both helium and hydro- tube is heated by the coil: and some heat is trans-

gen have high and similar thermal conductivities. ferred to the downstream sensor. The sensor coils

Accordingly, argon or nitrogen is used because are connected in a Wheatstone bridge circuit. The

eilher has a much lower thermal conductivity than out-of-balance signal from the bridge, caused by

hydrogen, resulting in a larger difference in ther- the difference in temperatures and hence resis-

mal conductivity and greater output. tance of the upstream and downstream coils,

The flow rate of carrier gas affects both the depends on the mass-flow rate of gas through

retention time of a compound in the column, the tube, and on the specific heat of the gas.

and the shape of the chromatographic peak and (See also Chapter 1, Section 1.3.) The signal,

hence the amplitude of the detector signal. It is suitably amplified, can be used to give a direct

therefore essential for the flow rate to be readily readout of the flow rate of gas through the tube,

adjustable to constant known values. The gas is and can be used to control the flow by feeding the

usually supplied from bottles, with pressure redu- signal to open or close a regulating valve in the

cing valves to reduce the pressure to a level com- main gas line downstream of the sensing device.

patible with the flow control equipment, and In cases where the carrier gas flow rate is con-

sufficient to give the required flow rate through trolled mechanically, a rotameter is provided to

the column and detector. indicate the flow rate. However, the best indi-

The flow rate of carrier gas may be measured cation of correct flow is often the analysis record

and controlled either mechanically or electron- itself, as the retention times of known components