Page 411 - Instrumentation Reference Book 3E

P. 411

394 Chemical analysis: gas analysis

sensor, and flammable gases in the sample are Element 1

continuously oxidized, releasing heat and raising compensator

the temperature of the sensor. Temperature

variations in the sensor are monitored to give a

continuous record of the flammable-gas concen-

tration in the sample.

The most suitable metals for promoting the D.C.

oxidation of molecules containing C-H bonds,

such as methane and other organic species, are

those in Group 8 of the Periodic Table, particu-

larly platinum and palladium. The temperature Element 2/

sensor is usually a platinum resistance thermo-

meter, wound in a coil and also used as the elec-

trical heater for the sensor. The resistance is

measured by connecting the sensor as one arm

of a Wheatstone bridge and measuring the out-

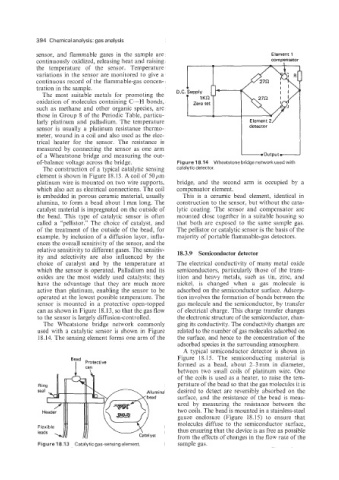

of-balance voltage across the bridge. Figure 18.14 Wheatstone bridge networkused with

The construction of a typical catalytic sensing catalytic detector.

element is shown in Figure 18.13. A coil of 50pm

platinum wire is mounted on two wire supports, bridge, and the second arm is occupied by a

which also act as electrical connections. The coil compensator element.

is embedded in porous ceramic material, usually This is a ceramic bead element, identical in

alumina, to form a bead about lmm long. The construction to the sensor, but without the cata-

catalyst material is impregnated on the outside of lytic coating. The sensor and compensator are

the bead. This type of catalytic sensor is often mounted close together in a suitable housing so

called a “pellistor.” The choice of catalyst, and that both are exposed to the same sample gas.

of the treatment of the outside of the bead, for The pellistor or catalytic sensor is the basis of the

example, by inclusion of a diffusion layer, influ- majority of portable flammable-gas detectors.

ences the overall sensitivity of the sensor, and the

relative sensitivity to different gases. The sensitiv- 18.3.9 Semiconductor detector

ity and selectivity are also influenced by the

choice of catalyst and by the temperature at The electrical conductivity of many metal oxide

which the sensor is operated. Palladium and its semiconductors, particularly those of the trans-

oxides are the most widely used catalysts; they ition and heavy metals, such as tin, zinc, and

have the advantage that they are much more nickel, is changed when a gas molecule is

active than platinum, enabling the sensor to be adsorbed on the semiconductor surface. Adsorp-

operated at the lowest possible temperature. The tion involves the formation of bonds between the

sensor is mounted in a protective open-topped gas molecule and the semiconductor, by transfer

can as shown in Figure 18.13, so that the gas flow of electrical charge. This charge transfer changes

to the sensor is largely diffusion-controlled. the electronic structure of the semiconductor, chan-

The Wheatstone bridge network commonly ging its conductivity. The conductivity changes are

used with a catalytic sensor is shown in Figure related to the number of gas molecules adsorbed on

18.14. The sensing element forms one arm of the the surface, and hence to the concentration of the

adsorbed species in the surrounding atmosphere.

A typical semiconductor detector is shown in

Figure 18.15. The semiconducting material is

formed as a bead, about 2-3mm in diameter,

between two small coils of platinum wire. One

of the coils is used as a heater, to raise the tem-

perature of the bead so that the gas molecules it is

desired to detect are reversibly absorbed on the

surface, and the resistance of the bead is meas-

ured by measuring the resistance between the

two coils. The bead is mounted in a stainless-steel

gauze enclosure (Figure 18.15) to ensure that

molecules diffuse to the semiconductor surface,

thus ensuring that the device is as free as possible

from the effects of changes in the flow rate of the

Figure 18.13 Catalytic gas-sensing element. sample gas.