Page 427 - Instrumentation Reference Book 3E

P. 427

410 Chemical analysis: gas analysis

Ambient air E 0 Converter

3

I Zero calibration

/ Dual head solenoid Reactor

-V-l

( pump 1

Span gas- '\ I

\

Sample in

Calibration Pressure

solenoid gauge r

I 1

\ Flowmeter

Back pressure

regulator

Exhaust gas

I 3 I

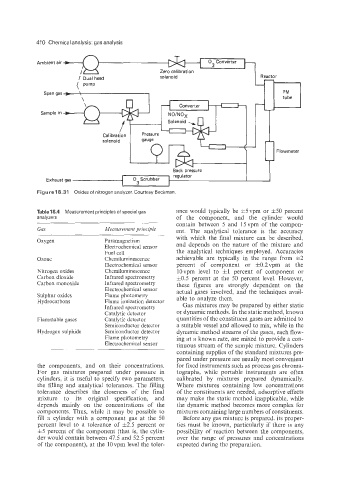

Figure 18.31 Oxides of nitrogen analyzer. Courtesy Beckman

Table 18.4 Measurement principles of special gas ance would typically be +5vpm or f50 percent

analyzers of the component, and the cylinder would

contain between 5 and 15 vpm of the compon-

Gus Measurement principle ent. The analytical tolerance is the accuracy

~ with which the final mixture can be described,

Oxygen Paramagnetism

Electrochemical sensor and depends on the nature of the mixture and

Fuel cell the analytical techniques employed. Accuracies

Ozone Chemiluminescence achievable are typically in the range from 52

Electrochemical sensor percent of component or f0.2vpm at the

Nitrogen oxides Chemiluminescence lOvpm level to +1 percent of component or

Carbon dioxide Infrared spectrometry +OS percent at the 50 percent level. However,

Carbon monoxide Infrared spectrometry these figures are strongly dependent on the

Electrochemical sensor actual gases involved, and the techniques avail-

Sulphur oxides Flame photometry able to analyze them.

Hydrocarbons Flame ionization detector

Infrared spectrometry Gas mixtures may be prepared by either static

Catalytic detector or dynamic methods. In the static method, known

Flammable gases Catalytic detector quantities of the constituent gases are admitted to

Semiconductor detector a suitable vessel and allowed to mix, while in the

Hydrogen sulphide Semiconductor detector dynamic method streams of the gases, each flow-

Flame photometry ing at a known rate, are mixed to provide a con-

Electrochemical sensor tinuous stream of the sample mixture. Cylinders

containing supplies of the standard mixtures pre-

pared under pressure are usually most convenient

the components, and on their concentrations. for fixed instruments such as process gas chroma-

For gas mixtures prepared under pressure in tographs, while portable instruments are often

cylinders, it is useful to specify two parameters, calibrated by mixtures prepared dynamically.

the filling and analytical tolerances. The filling Where mixtures containing low concentrations

tolerance describes the closeness of the final of the constituents are needed, adsorptive effects

mixture to its original specification, and may make the static method inapplicable, while

depends mainly on the concentrations of the the dynamic method becomes more complex for

components. Thus, while it may be possible to mixtures containing large numbers of constituents.

fill a cylinder with a component gas at the 50 Before any gas mixture is prepared, its proper-

percent level to a tolerance of 4~2.5 percent or ties must be known, particularly if there is any

&5 percent of the component (that is, the cylin- possibility of reaction between the components,

der would contain between 47.5 and 52.5 percent over the range of pressures and concentrations

of the component), at the 10 vpm level the toler- expected during the preparation.