Page 53 - Instrumentation Reference Book 3E

P. 53

38 Measurement of flow

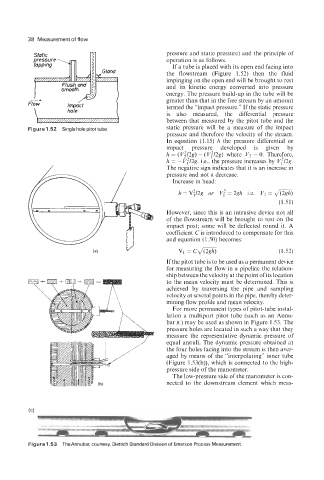

Sfafic I’ pressure and static pressure) and the principle of

presgure-Yn] operation is as follows.

taPPml !I If a tube is placed with its open end facing into

the flowstream (Figure 1.52) then the fluid

impinging on the open end will be brought to rest

and its kinetic energy converted into pressure

energy. The pressure build-up in the tube will be

greater than that in the free stream by an amount

termed the “impact pressure.” If the static pressure

is also measured, the differential pressure

between that measured by the pitot tube and the

Figure 1.52 Single hole pitot tube. static pressure will be a measure of the impact

pressure and therefore the velocity of the stream.

In equation (1.15) h the pressure differential or

impact pressure developed is given by

h = (V2212g) - (V;/2g) where V, = 0. Therefore,

h = - V:/2g, Le., the pressure increases by V:/2g.

The negative sign indicates that it is an increase in

pressure and not a decrease.

Increase in head:

h = V:/2g or V: = 2gh Le. VI = &@$

(1.51)

However, since this is an intrusive device not all

of the flowstream will be brought to rest on the

impact post; some will be deflected round it. A

coefficient C is introduced to compensate for this

and equation (1.50) becomes:

VI = c m (1.52)

If the pitot tube is to be used as a permanent device

for measuring the flow in a pipeline the relation-

ship between the velocity at the point of its location

to the mean velocity must be determined. This is

achieved by traversing the pipe and sampling

velocity at several points in the pipe, thereby deter-

mining flow profile and mean velocity.

For more permanent types of pitot-tube instal-

lation a multiport pitot tube (such as an Annu-

bar@) may be used as shown in Figure l .53. The

pressure holes are located in such a way that they

measure the representative dynamic pressure of

equal annuli. The dynamic pressure obtained at

the four holes facing into the stream is then aver-

aged by means of the “interpolating” inner tube

(Figure 1.53(b)), which is connected to the high-

pressure side of the manometer.

The low-pressure side of the manometer is con-

nected to the downstream element which meas-

Figure 1.53 The Annubar, courtesy, Dietrich Standard Division of Emerson Process Measurement.