Page 577 - Instrumentation Reference Book 3E

P. 577

Detector = Mechanical measurements 559

portable box, have been made to detect the level

of liquid COz in high-pressure cylinders. This is a

Detector (high level)

much simpler method than that of weighing the

cylinder and subtracting this value from the

Control

weight when the cylinder was originally received.

(low

level)

23.3.1.2 Using neutrons

u Some industrial materials have a very low atomic

Figure 23.11 Dual detector level gauge. number (9, such as oils. water, plastics, etc., and

by using a beam of fast neutrons from a source

such as l4lAmlBe or 25ZCf, and a suitable thermal-

Chart

Servosystem recorder neutron detector such as cerium-activated lithium

glass in a scintillation counter, or "BF; or 3He gas-

filled counters, it is possible to measure the level of

such material (Figure 23.13). Fast neutrons from

the source are moderated or slowed down by the

low-Z material and some are scattered back into

the detector. By mounting both the source of fast

neutrons and the slow neutron detector at one side

of the vessel the combination may be used to fol-

low a varying level using a servocontrolled

mechanism, or in a fixed position to control the

Figurc 23.12 Level gauge (continuous) with automatic level in the container to a preset position. This

control.

device is also usable as a portable detector system

of a level gauge is to select a radioactive source to to find blockages in pipes. valves, etc., which often

give the optimum path difference signal when the occur in plastics-manufacturing plants.

material or liquid to be monitored just obscures

the beam from source to detector. The absorption

of the beam by the wall of the container must be 23.3.2 Measurement of flow

taken into account, as well as the absorption of

the material being measured. A single source and There are several methods of measuring flow

using radioactive sources, as follows.

single detector will provide a single response, but

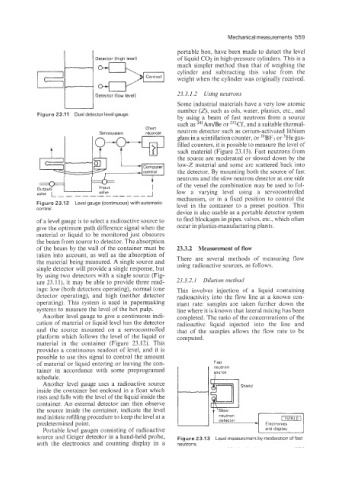

by using two detectors with a single source (Fig-

ure 23.1 l), it may be able to provide three read- 23.3.2.1 Dilution nietlzod

ings: low (both detectors operating), normal (one This involves injection of a liquid containing

detector operating), and high (neither detector radioactivity into the flow line at a known con-

operating). This system is used in papermaking stant rate: samples are taken further down the

systems to measure the level of the hot pulp. line where it is known that lateral mixing has been

Another level gauge to give a continuous indi- completed. The ratio of the concentrations of the

cation of material or liquid level has the detector radioactive liquid injected into the line and

and the source mounted on a servocontrolled that of the samples allows the flow rate to be

platform which follows the level of the liquid or computed.

material in the container (Figure 23.12). This

provides a continuous readout of level, and it is

possible to use this signal to control the amount

of material or liquid entering or leaving the con- Fast

tainer in accordance with some preprogramed neutron

source

schedule.

Another level gauge uses a radioactive source Shield

inside the container but enclosed in a float which

rises and falls with the level of the liquid inside the

container. An external detector can then observe

the source inside the container, indicate the level

and initiate refilling procedure to keep the level at a

predetermined point. Electronics

Portabie level gauges consisting of radioactive and display

source and Geiger detector in a hand-held probe, Figure 23.13 Level measurement by moderation of fast

with ithe electronics and counting display in a neutrons.