Page 575 - Instrumentation Reference Book 3E

P. 575

Materials analysis 557

without disturbing the source. Steam tracing or in powder form is extracted from the main stream

electrical heating can be arranged for samples by a screw conveyor and fed into a hopper. In the

likely to freeze. The output of the high-resolution powder-presentation unit the powder is extracted

propo'rtional counter, capable of high count rates from the hopper and fed on to a continuously

for statistical accuracy. is amplified and applied to weighted sample presenter at a rate which is con-

a counter and digital-to-analog converter when trolled so as to maintain a constant mass of sam-

required. Thus both digital and analog outputs ple per unit area on the latter within very close

are available for display and control purposes. limits. After measurement, the sample is returned

The meter has a range of up to 0-6 percent to the process. A system is fitted to provide an

sulfur by weight and indicates with a precision alarm if the mass per unit area of sample wanders

of TtO.01 percent sulfur by weight or &l percent outside preset limits. and aspiration is provided

of the indicated weight, whichever is the larger. It to eliminate airborne dust in the vicinity of the

is independent of carbon-hydrogen ratio from 6: 1 sample presenter and measuring head.

to 10:1 and the integrating times are from 10 to Under these conditions it is possible to make

200 s. The flow cell is suitable for pressures up to precise reproducible X-ray fluorescence measure-

15 bar and temperatures up to 15O"C, the tem- inents of elements from atomic number 19

perature range for the electronics being -10 to upwards without pelletizing.

+45 "IC. The signal from the X-ray detector in the pow-

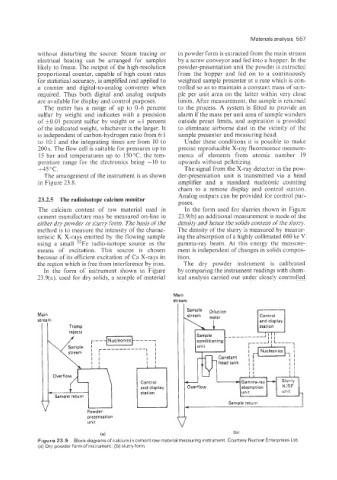

The arrangement of the instrument is as shown der-presentation unit is transmitted via a head

in Figure 23.8. amplifier and a standard nucleonic counting

chain to a remote display and control station.

Analog outputs can be provided for control pur-

23.2.5 The radioisotope calcium monitor

poses.

The calcium content of raw material used in In the form used for slurries shown in Figure

cement manufacture may be measured on-line in 23.9(b) an additional measurement is made of the

either dry powder or slurry form. The basis of the density and hence the solids content of the slurry.

method is to measure the intensity of the charac- The density of the slurry is measured by measur-

teristic K X-rays emitted by the flowing sample ing the absorption of a highly collimated 660 ke V

using a small j'Fe radio-isotope source as the gamma-ray beam. At this energy the measure-

meanis of excitation. This source is chosen ment is independent of changes in solids CO~~QS-

because of its efficient excitation of Ca X-rays in itioii.

the region which is free from interference by iron. The dry powder instrument is calibrated

In the form of instrument shown iii Figure by comparing the instrument readings with chem-

23.9(a). used for dry solids, a sample of material ical analysis carried out under closely controlled

Main

Main

! B m

Tramp

rejects

\

Powder-

presentation

unit

(a)

Figure 23.9 Block diagrams of calcium in cement raw material measuring instrument. Courtesy Nuclear Enterprises Ltd

(a) Dry powder form of instrumen:; (b) slurry form.