Page 579 - Instrumentation Reference Book 3E

P. 579

Mechanical measurements 561

radiation falls to a finite area; and if the thickness is

constant and known the reading will be a measure

of the density.

1 - p

Sl

............

..........

.........

...........

.....

........

23.3.3.2 Measurement of coating thickness ...........

1111

In industry a wide variety of processes occur

where it is necessary to measure and sometimes

automatically control the thickness of a coating

appkd to a base material produced in strip form.

Examples of such processes are the deposition of

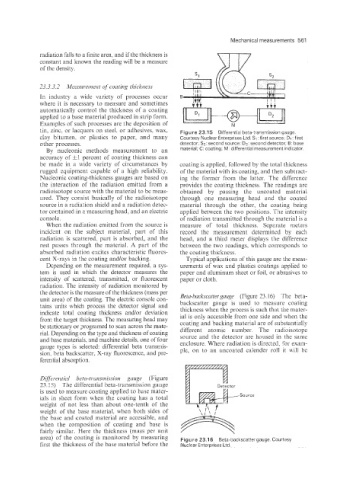

tin, zinc: or lacquers on steel, or adhesives, wax, Figure 23.15 Differential beta-transmission gauge.

clay bitumen, or plastics to paper, and many Courtesy Nuclear Enterprises Ltd. SI :first source; D1 : first

other processes. detector; S2: second source; Dz: second detector; B: base

By nucleonic methods measurement to an material; C: coating; M: differential measurement indicator.

accuracy of 2~1 percent of coating thickness can

be made in a wide variety of circumstances by coating is applied, followed by the total thickness

rugged equipment capable of a high reliability. of the material with its coating, and then subtract-

Nucleonic coating-thickness gauges are based on ing the former from the latter. The difference

the interaction of the radiation emitted from a provides the coating thickness. The readings are

radioisotope source with the material to be meas- obtained by passing the uncoated material

ured. They consist basically of the radioisotope through one measuring head and the coated

source in a radiation shield and a radiation detec- material through the other, the coating being

tor contained in a measuring head, and an electric applied between the two positions. The intensity

console. of radiation transmitted through the material is a

When the radiation emitted from the source is measure of total thickness. Separate meters

incidlent on the subject material, part of this record the measurement determined by each

radiation is scattered, part is absorbed, and the head, and a third meter displays the difference

rest lmsses through the material. A part of the between the two readings, which corresponds to

absorbed radiation excites characteristic fluores- the coating thickness.

cent X-rays in the coating andlor backing. Typical applications of this gauge are the meas-

Depending on the measurement required, a sys- urements of wax and plastics coatings applied to

tem is used in which the detector measures the paper and aluminum sheet or foil, or abrasives to

intensity of scattered, transmitted, or fluorescent paper or cloth.

radiation. The intensity of radiation monitored by

the detector is the measure of the thickness (mass per Betu-backscatter gauge (Figure 23.16) The beta-

unit area) of the coating. The electric console con-

tains units which prolcess the detector signal and backscatter gauge is used to measure coating

indicate total coating thickness andlor deviation thickness when the process is such that the mater-

ial is only accessible from one side and when the

from the target thickness. The measuring head may coating and backing material are of substantially

be stationary or programed to scan across the mate- different atomic number. The radioisotope

rial. Depending on the type and thickness of coating source and the detector are housed in the same

and base materials, and machine details, one of four

gauge types is selected: differential beta transmis- enclosure. Where radiation is directed, for exam-

sion, beta backscatter, X-ray fluorescence, and pre- ple, on to an uncoated calender roll it will be

ferential absorption.

Differential beta-transmission gauge (Figure

23.15) The differential beta-transmission gauge

is used to measure coating applied to base mater-

ials in sheet form when the coating has a total Source

weight of not less than about one-tenth of the

weiglht of the base material. when both sides of

the base and coated material are accessible, and

when the composition of coating and base is

fairly similar. Here the thickness (mass per unit

area) of the coating is monitored by measuring Figure 23.1 6 Beta-backscatter gauge. Courtesy

first the thickness of the base material before the Nuclear Enterprises Ltd.