Page 609 - Instrumentation Reference Book 3E

P. 609

Underwater non-destructive testing 591

Wincl ne

safety

cut-outs

Sea level

Parallel conductor

center

line

I

Hand-held ultraviolet

with ink dispenser

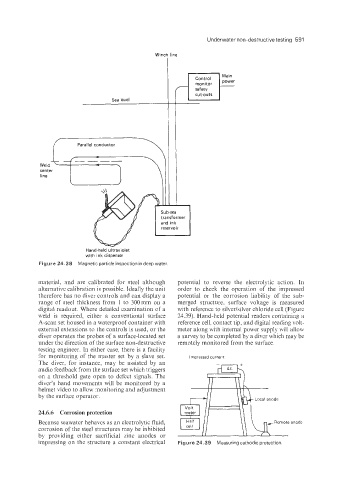

Figure 24.38 Magnetic particle inspection in deep water.

material, and are calibrated for steel although potential to reverse the electrolytic action. In

alternative calibration is possible. Ideally the unit order to check the operation of the impressed

therefore has no diver controls and can display a potential or the corrosion liability of the sub-

range of steel thickness from 1 to 300mm on a merged structure, surface voltage is measured

digital readout. Where detailed examination of a with reference to silver/silver chloride cell (Figure

weld is required, either a conventional surface 24.39). Hand-held potential readers containing a

A-scan set housed in a waterproof container with reference cell, contact tip, and digital reading volt-

external extensions to the controls is used, or the meter along with internal power supply will allow

diver operates the probes of a surface-located set a survey to be completed by a diver which may be

under the direction of the surface non-destructive remotely monitored from the surface.

testing engineer. In either case, there is a facility

for monitoring of the master set by a slave set. impressed current

The diver, for instance, may be assisted by an

audio feedback from the surface set which triggers

on a threshold gate open to defect signals. The

diver's hand movements will be monitored by a

helmet video to allow monitoring and adjustment

by the surface operator.

24.6.61 Corrosion protection

Because seawater behaves as an electrolytic fluid, anode

corrosion of the steel structures may be inhibited

by providing either sacrificial zinc anodes or

impressing on the structure a constant electrical Figure 24.39 Measuring cathodic protection.