Page 604 - Instrumentation Reference Book 3E

P. 604

586 Non-destructive testing

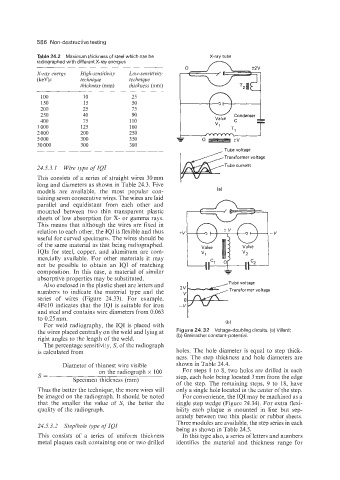

Table 24.2 Maximum thickness of steel which can be X-ray tube

radiographed with different X-ray energies

X-ray ene~gy High-sensitivity Low-sensitivity

(keV)s technique tech ique

thickness (mm) thickness (mm)

100 IO 25

150 15 50

200 25 75

250 40 90

400 75 110

1000 125 160

2 000 200 250 1

5 000 300 3 50 0 rv

30 000 300 380 w

Tube voltage

Tube current

24.5.3.1 Wire type of IQI Transformer voltage

This consists of a series of straight wires 30mm (a)

long and diameters as shown in Table 24.3. Five

models are available, the most popular con-

taining seven consecutive wires. The wires are laid

parallel and equidistant from each other and n

mounted between two thin transparent plastic

sheets of low absorption for X- or gamma rays.

This means that although the wires are fixed in

relation to each other, the IQI is flexible and thus -V

useful for curved specimens. The wires should be

of the same material as that being radiographed.

IQIs for steel, copper, and aluminum are com-

mercially available. For other materials it may

not be possible to obtain an IQI of matching

composition. In this case, a material of similar *:p

absorptive properties may be substituted.

Also enclosed in the plastic sheet are letters and Tube voltage

numbers to indicate the material type and the Transformer voltage

series of wires (Figure 24.33). For example,

4Fe10 indicates that the IQI is suitable for iron -V

and steel and contains wire diameters from 0.063

to 0.25 mm.

For weld radiography, the IQI is placed with Ib)

the wires placed centrally on the weld and lying at Figure 24.32 Voltage-doubling circuits. (a) Villard:

right angles to the length of the weld. (b) Greinacher constant-potential.

The percentage sensitivity, S, of the radiograph

is calculated from holes. The hole diameter is equal to step thick-

ness. The step thickness and hole diameters are

Diameter of thinnest wire visible shown in Table 24.4.

on the radiograph x 100 For steps 1 to 8, two holes are drilled in each

S= step, each hole being located 3 mm from the edge

Specimen thickness (mm)

of the step. The remaining steps, 9 to lS, have

Thus the better the technique, the more wires will only a single hole located in the center of the step.

be imaged on the radiograph. It should be noted For convenience, the IQI may be machined as a

that the smaller the value of S, the better the single step wedge (Figure 24.34). For extra flexi-

quality of the radiograph. bility each plaque is mounted in line but sep-

arately between two thin plastic or rubber sheets.

Three modules are available, the step series in each

24.5.3.2 Steplhole type of IQI

being as shown in Table 24.5.

This consists of a series of uniform thickness In this type also, a series of letters and numbers

metal plaques each containing one or two drilled identifies the material and thickness range for