Page 161 - Introduction to Computational Fluid Dynamics

P. 161

P1: IWV

12:28

May 20, 2005

CB908/Date

0521853265c05

140

1.0 0 521 85326 5 2D CONVECTION – CARTESIAN GRIDS

4

5 F 80.00

6

E 77.86

JB4 D 75.71

0.8 7

C 73.57

IB2 B 71.43

STEEL

JB3 A 69.29

0.6

9 67.14

8 65.00 Figure 5.13. Isotherms – conduction in a re-

IB1 CONCRETE

7 62.86 inforced cement concrete slab.

0.4

6 60.71

JB2 5 58.57

4 56.43

8

JB1 3 54.29

0.2 9

A 2 52.14

B

C 1 50.00

D

E

0.0 F

0.25 0.5

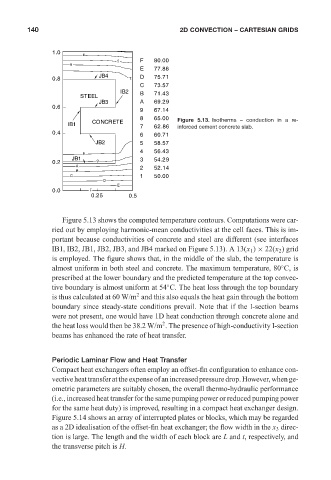

Figure 5.13 shows the computed temperature contours. Computations were car-

ried out by employing harmonic-mean conductivities at the cell faces. This is im-

portant because conductivities of concrete and steel are different (see interfaces

IB1, IB2, JB1, JB2, JB3, and JB4 marked on Figure 5.13). A 13(x 1 ) × 22(x 2 ) grid

is employed. The figure shows that, in the middle of the slab, the temperature is

◦

almost uniform in both steel and concrete. The maximum temperature, 80 C, is

prescribed at the lower boundary and the predicted temperature at the top convec-

tive boundary is almost uniform at 54 C. The heat loss through the top boundary

◦

2

is thus calculated at 60 W/m and this also equals the heat gain through the bottom

boundary since steady-state conditions prevail. Note that if the I-section beams

were not present, one would have 1D heat conduction through concrete alone and

2

the heat loss would then be 38.2 W/m . The presence of high-conductivity I-section

beams has enhanced the rate of heat transfer.

Periodic Laminar Flow and Heat Transfer

Compact heat exchangers often employ an offset-fin configuration to enhance con-

vectiveheattransferattheexpenseofanincreasedpressuredrop.However,whenge-

ometric parameters are suitably chosen, the overall thermo-hydraulic performance

(i.e., increased heat transfer for the same pumping power or reduced pumping power

for the same heat duty) is improved, resulting in a compact heat exchanger design.

Figure 5.14 shows an array of interrupted plates or blocks, which may be regarded

as a 2D idealisation of the offset-fin heat exchanger; the flow width in the x 3 direc-

tion is large. The length and the width of each block are L and t, respectively, and

the transverse pitch is H.