Page 338 - Introduction to Information Optics

P. 338

6.3. Thin-Film Waveguide Couplers

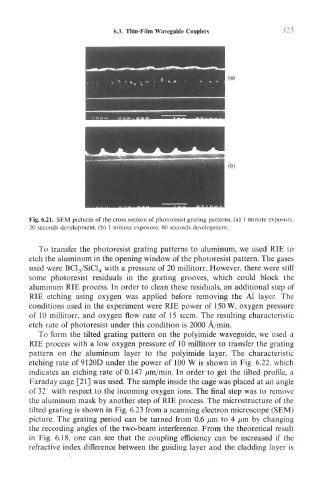

Fig. 6.21. SEM pictures of the cross section of photoresist grating patterns, (a) 1 minute exposure,

30 seconds development, (b) 1 minute exposure, 60 seconds development.

To transfer the photoresist grating patterns to aluminum, we used RLE to

etch the aluminum in the opening window of the photoresist pattern. The gases

used were BCl 3/SiCl 4 with a pressure of 20 millitorr. However, there were still

some photoresist residuals in the grating grooves, which could block the

aluminum RIE process. In order to clean these residuals, an additional step of

RIE etching using oxygen was applied before removing the Al layer. The

conditions used in the experiment were RIE power of 150 W, oxygen pressure

of 10 millitorr, and oxygen flow rate of 15 seem. The resulting characteristic

etch rate of photoresist under this condition is 2000 A/min.

To form the tilted grating pattern on the polyimide waveguide, we used a

RIE process with a low oxygen pressure of 10 millitorr to transfer the grating

pattern on the aluminum layer to the polyimide layer. The characteristic

etching rate of 9120D under the power of 100 W is shown in Fig. 6.22, which

indicates an etching rate of 0.147 ^m/min. In order to get the tilted profile, a

Faraday cage [21] was used. The sample inside the cage was placed at an angle

of 32 with respect to the incoming oxygen ions. The final step was to remove

the aluminum mask by another step of RIE process. The microstructure of the

tilted grating is shown in Fig. 6.23 from a scanning electron microscope (SEM)

picture. The grating period can be turned from 0.6 jum to 4 /im by changing

the recording angles of the two-beam interference. From the theoretical result

in Fig. 6.18, one can see that the coupling efficiency can be increased if the

refractive index difference between the guiding layer and the cladding layer is