Page 229 - Introduction to Mineral Exploration

P. 229

212 M.K.G. WHATELEY & B. SCOTT

36.2 tonnes (80,000 lb)

bulk sample

18.1 tonnes for 18.1 tonnes

test work crushed to minus 32 mm

32 mm screen

ROTARY SPLITTER (4:1)

14.5 tonnes 3.6 tonnes

crushed to minus 10 mm

10 mm screen

SPLIT

3020 kg 580 kg

23 cm × 30 cm roll

crusher to minus 5 mm

SPLIT

Rejects 72 kg

446 kg

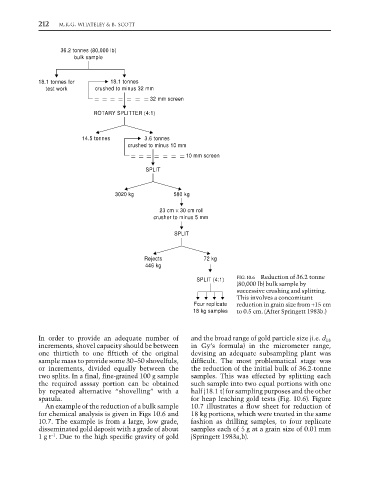

SPLIT (4:1) FIG. 10.6 Reduction of 36.2 tonne

(80,000 lb) bulk sample by

successive crushing and splitting.

This involves a concomitant

Four replicate reduction in grain size from +15 cm

18 kg samples to 0.5 cm. (After Springett 1983b.)

In order to provide an adequate number of and the broad range of gold particle size (i.e. d lib

increments, shovel capacity should be between in Gy’s formula) in the micrometer range,

one thirtieth to one fiftieth of the original devising an adequate subsampling plant was

sample mass to provide some 30–50 shovelfuls, difficult. The most problematical stage was

or increments, divided equally between the the reduction of the initial bulk of 36.2-tonne

two splits. In a final, fine-grained 100 g sample samples. This was effected by splitting each

the required asssay portion can be obtained such sample into two equal portions with one

by repeated alternative “shovelling” with a half (18.1 t) for sampling purposes and the other

spatula. for heap leaching gold tests (Fig. 10.6). Figure

An example of the reduction of a bulk sample 10.7 illustrates a flow sheet for reduction of

for chemical analysis is given in Figs 10.6 and 18 kg portions, which were treated in the same

10.7. The example is from a large, low grade, fashion as drilling samples, to four replicate

disseminated gold deposit with a grade of about samples each of 5 g at a grain size of 0.01 mm

−1

1gt . Due to the high specific gravity of gold (Springett 1983a,b).