Page 263 - Introduction to Mineral Exploration

P. 263

246 M.K.G. WHATELEY & B. SCOTT

Load Axial stress

(a) σ (b) σ 1

σ 1

Seal Shear fracture

Steel σ

σ n

cylinder

θ

σ

σ

σ

σ

σ σ Borehole core σ 2 =σ 3 τ σ 2 =σ 3

σ 2 =σ 3

Confining Confining

pressure pressure

Flexible membrane

Fluid filled

chamber

Pressure from pump

σ 2

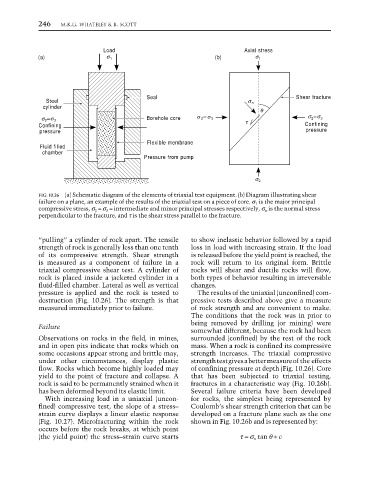

FIG. 10.26 (a) Schematic diagram of the elements of triaxial test equipment. (b) Diagram illustrating shear

failure on a plane, an example of the results of the triaxial test on a piece of core. σ 1 is the major principal

compressive stress, σ 2 = σ 3 = intermediate and minor principal stresses respectively, σ n is the normal stress

perpendicular to the fracture, and τ is the shear stress parallel to the fracture.

“pulling” a cylinder of rock apart. The tensile to show inelastic behavior followed by a rapid

strength of rock is generally less than one tenth loss in load with increasing strain. If the load

of its compressive strength. Shear strength is released before the yield point is reached, the

is measured as a component of failure in a rock will return to its original form. Brittle

triaxial compressive shear test. A cylinder of rocks will shear and ductile rocks will flow,

rock is placed inside a jacketed cylinder in a both types of behavior resulting in irreversible

fluid-filled chamber. Lateral as well as vertical changes.

pressure is applied and the rock is tested to The results of the uniaxial (unconfined) com-

destruction (Fig. 10.26). The strength is that pressive tests described above give a measure

measured immediately prior to failure. of rock strength and are convenient to make.

The conditions that the rock was in prior to

being removed by drilling (or mining) were

Failure

somewhat different, because the rock had been

Observations on rocks in the field, in mines, surrounded (confined) by the rest of the rock

and in open pits indicate that rocks which on mass. When a rock is confined its compressive

some occasions appear strong and brittle may, strength increases. The triaxial compressive

under other circumstances, display plastic strength test gives a better measure of the effects

flow. Rocks which become highly loaded may of confining pressure at depth (Fig. 10.26). Core

yield to the point of fracture and collapse. A that has been subjected to triaxial testing,

rock is said to be permanently strained when it fractures in a characteristic way (Fig. 10.26b).

has been deformed beyond its elastic limit. Several failure criteria have been developed

With increasing load in a uniaxial (uncon- for rocks, the simplest being represented by

fined) compressive test, the slope of a stress– Coulomb’s shear strength criterion that can be

strain curve displays a linear elastic response developed on a fracture plane such as the one

(Fig. 10.27). Microfracturing within the rock shown in Fig. 10.26b and is represented by:

occurs before the rock breaks, at which point

(the yield point) the stress–strain curve starts τ = σ n tan θ + c