Page 236 - System on Package_ Miniaturization of the Entire System

P. 236

210 Cha pte r F o u r

the design cycle. In this section, the effect of process variations on the electrical

performance is discussed along with a framework for including these variations into

the design process. The goal is to generate designs that are yieldable under the

assumption that catastrophic defects are minimized. Hence, the designs account for

parametric variations due to statistical deviations in the process variables.

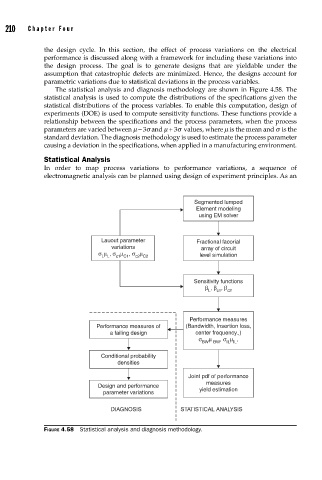

The statistical analysis and diagnosis methodology are shown in Figure 4.58. The

statistical analysis is used to compute the distributions of the specifications given the

statistical distributions of the process variables. To enable this computation, design of

experiments (DOE) is used to compute sensitivity functions. These functions provide a

relationship between the specifications and the process parameters, when the process

parameters are varied between m – 3s and m + 3s values, where m is the mean and s is the

standard deviation. The diagnosis methodology is used to estimate the process parameter

causing a deviation in the specifications, when applied in a manufacturing environment.

Statistical Analysis

In order to map process variations to performance variations, a sequence of

electromagnetic analysis can be planned using design of experiment principles. As an

Segmented lumped

Element modeling

using EM solver

Lauout parameter Fractional facorial

variations array of circuit

σ μ , σ μ , σ μ

L L c1 C1 c2 C2 level simulation

Sensitivity functions

β , β , β

L c1 c2

Performance measures

Performance measures of (Bandwidth, Insertion loss,

a failing design center frequency.,)

σ μ , σ μ ,

BW BW IL IL

Conditional probability

densities

Joint pdf of performance

measures

Design and performance

parameter variations yield estimation

DIAGNOSIS STATISTICAL ANALYSIS

FIGURE 4.58 Statistical analysis and diagnosis methodology.