Page 191 - Sami Franssila Introduction to Microfabrication

P. 191

170 Introduction to Microfabrication

4

2

4

2

4

2

3 3 3 c

<001> 2

1 1 1 1

<110>

W d

<110> Si substrate

(a) (b)

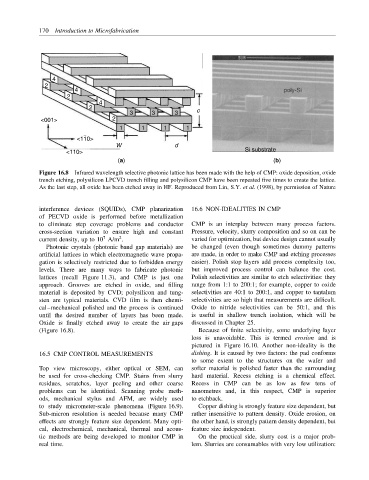

Figure 16.8 Infrared wavelength selective photonic lattice has been made with the help of CMP: oxide deposition, oxide

trench etching, polysilicon LPCVD trench filling and polysilicon CMP have been repeated five times to create the lattice.

As the last step, all oxide has been etched away in HF. Reproduced from Lin, S.Y. et al. (1998), by permission of Nature

interference devices (SQUIDs), CMP planarization 16.6 NON-IDEALITIES IN CMP

of PECVD oxide is performed before metallization

to eliminate step coverage problems and conductor CMP is an interplay between many process factors.

cross-section variation to ensure high and constant Pressure, velocity, slurry composition and so on can be

2

7

current density, up to 10 A/m . varied for optimization, but device design cannot usually

Photonic crystals (photonic band gap materials) are be changed (even though sometimes dummy patterns

artificial lattices in which electromagnetic wave propa- are made, in order to make CMP and etching processes

gation is selectively restricted due to forbidden energy easier). Polish stop layers add process complexity too,

levels. There are many ways to fabricate photonic but improved process control can balance the cost.

lattices (recall Figure 11.3), and CMP is just one Polish selectivities are similar to etch selectivities: they

approach. Grooves are etched in oxide, and filling range from 1:1 to 200:1; for example, copper to oxide

material is deposited by CVD; polysilicon and tung- selectivities are 40:1 to 200:1, and copper to tantalum

sten are typical materials. CVD film is then chemi- selectivities are so high that measurements are difficult.

cal–mechanical polished and the process is continued Oxide to nitride selectivities can be 50:1, and this

until the desired number of layers has been made. is useful in shallow trench isolation, which will be

Oxide is finally etched away to create the air gaps discussed in Chapter 25.

(Figure 16.8). Because of finite selectivity, some underlying layer

loss is unavoidable. This is termed erosion and is

pictured in Figure 16.10. Another non-ideality is the

16.5 CMP CONTROL MEASUREMENTS dishing. It is caused by two factors: the pad conforms

to some extent to the structures on the wafer and

Top view microscopy, either optical or SEM, can softer material is polished faster than the surrounding

be used for cross-checking CMP. Stains from slurry hard material. Recess etching is a chemical effect.

residues, scratches, layer peeling and other coarse Recess in CMP can be as low as few tens of

problems can be identified. Scanning probe meth- nanometres and, in this respect, CMP is superior

ods, mechanical stylus and AFM, are widely used to etchback.

to study micrometer-scale phenomena (Figure 16.9). Copper dishing is strongly feature size dependent, but

Sub-micron resolution is needed because many CMP rather insensitive to pattern density. Oxide erosion, on

effects are strongly feature size dependent. Many opti- the other hand, is strongly pattern density dependent, but

cal, electrochemical, mechanical, thermal and acous- feature size independent.

tic methods are being developed to monitor CMP in On the practical side, slurry cost is a major prob-

real time. lem. Slurries are consumables with very low utilization: