Page 194 - Sami Franssila Introduction to Microfabrication

P. 194

17

Bonding and Layer Transfer

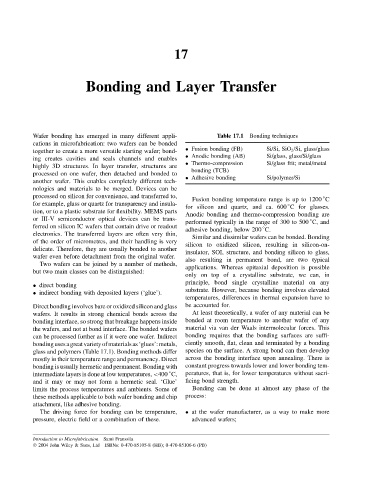

Wafer bonding has emerged in many different appli- Table 17.1 Bonding techniques

cations in microfabrication: two wafers can be bonded

together to create a more versatile starting wafer; bond- • Fusion bonding (FB) Si/Si, SiO 2 /Si, glass/glass

ing creates cavities and seals channels and enables • Anodic bonding (AB) Si/glass, glass/Si/glass

highly 3D structures. In layer transfer, structures are • Thermo-compression Si/glass frit; metal/metal

bonding (TCB)

processed on one wafer, then detached and bonded to • Adhesive bonding Si/polymer/Si

another wafer. This enables completely different tech-

nologies and materials to be merged. Devices can be

processed on silicon for convenience, and transferred to,

◦

Fusion bonding temperature range is up to 1200 C

for example, glass or quartz for transparency and insula-

for silicon and quartz, and ca. 600 C for glasses.

◦

tion, or to a plastic substrate for flexibility. MEMS parts

Anodic bonding and thermo-compression bonding are

or III-V semiconductor optical devices can be trans-

◦

performed typically in the range of 300 to 500 C, and

ferred on silicon IC wafers that contain drive or readout adhesive bonding, below 200 C.

◦

electronics. The transferred layers are often very thin, Similar and dissimilar wafers can be bonded. Bonding

of the order of micrometres, and their handling is very silicon to oxidized silicon, resulting in silicon-on-

delicate. Therefore, they are usually bonded to another insulator, SOI, structure, and bonding silicon to glass,

wafer even before detachment from the original wafer. also resulting in permanent bond, are two typical

Two wafers can be joined by a number of methods, applications. Whereas epitaxial deposition is possible

but two main classes can be distinguished:

only on top of a crystalline substrate, we can, in

principle, bond single crystalline material on any

• direct bonding

• indirect bonding with deposited layers (‘glue’). substrate. However, because bonding involves elevated

temperatures, differences in thermal expansion have to

Direct bonding involves bare or oxidized silicon and glass be accounted for.

wafers. It results in strong chemical bonds across the At least theoretically, a wafer of any material can be

bonding interface, so strong that breakage happens inside bonded at room temperature to another wafer of any

the wafers, and not at bond interface. The bonded wafers material via van der Waals intermolecular forces. This

can be processed further as if it were one wafer. Indirect bonding requires that the bonding surfaces are suffi-

bondingusesagreatvarietyofmaterialsas‘glues’:metals, ciently smooth, flat, clean and terminated by a bonding

glass and polymers (Table 17.1). Bonding methods differ species on the surface. A strong bond can then develop

mostly in their temperature range and permanency. Direct across the bonding interface upon annealing. There is

bonding is usually hermetic and permanent. Bonding with constant progress towards lower and lower bonding tem-

intermediate layers is done at low temperatures, <400 C, peratures, that is, for lower temperatures without sacri-

◦

and it may or may not form a hermetic seal. ‘Glue’ ficing bond strength.

limits the process temperatures and ambients. Some of Bonding can be done at almost any phase of the

these methods applicable to both wafer bonding and chip process:

attachment, like adhesive bonding.

The driving force for bonding can be temperature, • at the wafer manufacturer, as a way to make more

pressure, electric field or a combination of these. advanced wafers;

Introduction to Microfabrication Sami Franssila

2004 John Wiley & Sons, Ltd ISBNs: 0-470-85105-8 (HB); 0-470-85106-6 (PB)