Page 59 - Sami Franssila Introduction to Microfabrication

P. 59

38 Introduction to Microfabrication

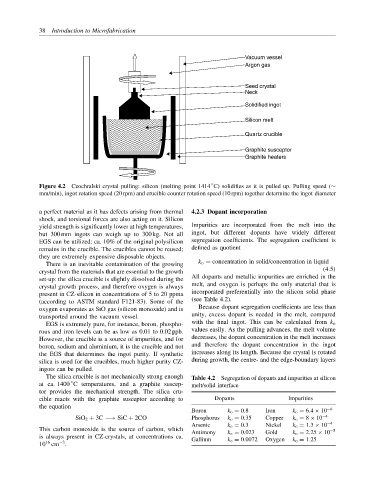

Vacuum vessel

Argon gas

Seed crystal

Neck

Solidified ingot

Silicon melt

Quartz crucible

Graphite susceptor

Graphite heaters

◦

Figure 4.2 Czochralski crystal pulling: silicon (melting point 1414 C) solidifies as it is pulled up. Pulling speed (∼

mm/min), ingot rotation speed (20 rpm) and crucible counter rotation speed (10 rpm) together determine the ingot diameter

a perfect material as it has defects arising from thermal 4.2.3 Dopant incorporation

shock, and torsional forces are also acting on it. Silicon

yield strength is significantly lower at high temperatures, Impurities are incorporated from the melt into the

but 300 mm ingots can weigh up to 300 kg. Not all ingot, but different dopants have widely different

EGS can be utilized: ca. 10% of the original polysilicon segregation coefficients. The segregation coefficient is

remains in the crucible. The crucibles cannot be reused; defined as quotient

they are extremely expensive disposable objects.

There is an inevitable contamination of the growing k o = concentration in solid/concentration in liquid

crystal from the materials that are essential to the growth (4.5)

set-up: the silica crucible is slightly dissolved during the All dopants and metallic impurities are enriched in the

crystal growth process, and therefore oxygen is always melt, and oxygen is perhaps the only material that is

present in CZ-silicon in concentrations of 5 to 20 ppma incorporated preferentially into the silicon solid phase

(according to ASTM standard F121-83). Some of the (see Table 4.2).

Because dopant segregation coefficients are less than

oxygen evaporates as SiO gas (silicon monoxide) and is

transported around the vacuum vessel. unity, excess dopant is needed in the melt, compared

EGS is extremely pure, for instance, boron, phospho- with the final ingot. This can be calculated from k o

rous and iron levels can be as low as 0.01 to 0.02 ppb. values easily. As the pulling advances, the melt volume

However, the crucible is a source of impurities, and for decreases, the dopant concentration in the melt increases

boron, sodium and aluminium, it is the crucible and not and therefore the dopant concentration in the ingot

the EGS that determines the ingot purity. If synthetic increases along its length. Because the crystal is rotated

silica is used for the crucibles, much higher purity CZ- during growth, the centre- and the edge-boundary layers

ingots can be pulled.

The silica crucible is not mechanically strong enough Table 4.2 Segregation of dopants and impurities at silicon

at ca. 1400 C temperatures, and a graphite suscep- melt/solid interface

◦

tor provides the mechanical strength. The silica cru-

cible reacts with the graphite susceptor according to Dopants Impurities

the equation

Boron k o = 0.8 Iron k o = 6.4 × 10 −6

SiO 2 + 3C −→ SiC + 2CO Phosphorus k o = 0.35 Copper k o = 8 × 10 −4

Arsenic k o = 0.3 Nickel k o = 1.3 × 10 −4

This carbon monoxide is the source of carbon, which −5

Antimony k o = 0.023 Gold k o = 2.25 × 10

is always present in CZ-crystals, at concentrations ca. Gallium k o = 0.0072 Oxygen k o = 1.25

−3

16

10 cm .