Page 70 - Sami Franssila Introduction to Microfabrication

P. 70

Thin-film Materials and Processes 49

films made by sputtering, evaporation, electroplating or

open source resistive heating → thermal evaporation

chemical vapour deposition (CVD) can have a factor

electron beam heating → e-beam evaporation

of 2 differences in resistivity or grain size. When an

equilibrium source heating → molecular beam

amorphous film is annealed at high temperature, it will

epitaxy (MBE)

crystallize. But its crystal size and crystal orientation,

argon ion bombardment → sputtering

and surface roughness will be different from a film

that was initially polycrystalline, even though the films laser beam bombardment → ablation

received identical anneals.

Very thin films are discontinuous and the thickness Shutter blades can be used to prevent deposition on

required for continuous films is process- and material- the wafers during unstable flux (e.g., at the start of the

dependent. One criterion is transparency, which can be deposition or during parameter ramping). Shutter blades

calculated from Lambert’s law: enable very accurate and abrupt interfaces to be made,

almost at the atomic thickness limit.

I = I o exp(−αx) = I o exp(−4πkx/λ) (5.1)

5.3 EVAPORATION AND MOLECULAR

With extinction coefficient (k) values 2 to 6 for metal BEAM EPITAXY

films in the visible range, this translates to ca. 10 to

Evaporation of elemental metals is fairly straightfor-

20 nm as a limit for transparency when a 1/e intensity

ward: heated metals have high vapour pressures and in

drop is used as a criterion.

high vacuum (HV), the evaporated atoms will be trans-

ported to the substrate (Figure 5.3). Atoms arrive at ther-

mal speeds, which results in basically room-temperature

5.2 PHYSICAL VAPOUR DEPOSITION (PVD)

deposition. Evaporation systems are either high-vacuum

(HV) or ultra high–vacuum (UHV) systems, with the

Physical vapour deposition is the dominant method for −11

best UHV deposition systems with 10 Torr base pres-

metallic thin-film deposition. All aluminum films in −12

sures, and 10 Torr oxygen partial pressures.

microfabrication are deposited by PVD, and PVD is used

There are very few parameters in evaporation that

for copper, refractory metals and for metal alloys and can be used to tailor film properties. There is no bom-

compounds like TiW, WN, TiN, MoSi 2 , ZnO and AlN. bardment in addition to thermalized atoms themselves,

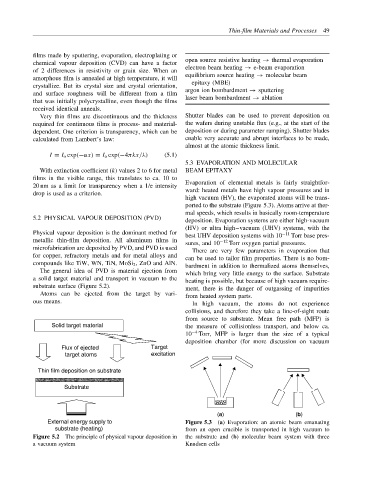

The general idea of PVD is material ejection from which bring very little energy to the surface. Substrate

a solid target material and transport in vacuum to the heating is possible, but because of high vacuum require-

substrate surface (Figure 5.2). ment, there is the danger of outgassing of impurities

Atoms can be ejected from the target by vari- from heated system parts.

ous means. In high vacuum, the atoms do not experience

collisions, and therefore they take a line-of-sight route

from source to substrate. Mean free path (MFP) is

Solid target material the measure of collisionless transport, and below ca.

10 −4 Torr, MFP is larger than the size of a typical

deposition chamber (for more discussion on vacuum

Flux of ejected Target

target atoms excitation

Thin film deposition on substrate

Substrate

(a) (b)

External energy supply to Figure 5.3 (a) Evaporation: an atomic beam emanating

substrate (heating) from an open crucible is transported in high vacuum to

Figure 5.2 The principle of physical vapour deposition in the substrate and (b) molecular beam system with three

a vacuum system Knudsen cells