Page 73 - Sami Franssila Introduction to Microfabrication

P. 73

52 Introduction to Microfabrication

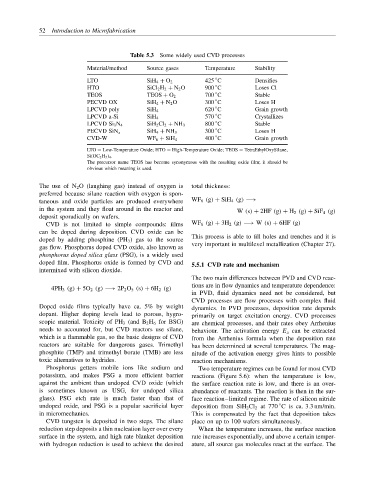

Table 5.3 Some widely used CVD processes

Material/method Source gases Temperature Stability

◦

LTO SiH 4 + O 2 425 C Densifies

◦

HTO SiCl 2 H 2 + N 2 O 900 C Loses Cl

◦

TEOS TEOS + O 2 700 C Stable

◦

PECVD OX SiH 4 + N 2 O 300 C Loses H

◦

LPCVD poly SiH 4 620 C Grain growth

◦

LPCVD a-Si SiH 4 570 C Crystallizes

◦

LPCVD Si 3 N 4 SiH 2 Cl 2 + NH 3 800 C Stable

◦

300 C Loses H

PECVD SiN x SiH 4 + NH 3

◦

CVD-W WF 6 + SiH 4 400 C Grain growth

LTO = Low-Temperature Oxide; HTO = High-Temperature Oxide; TEOS = TetraEthylOxySilane,

Si(OC 2 H 5 ) 4 .

The precursor name TEOS has become synonymous with the resulting oxide film; it should be

obvious which meaning is used.

The use of N 2 O (laughing gas) instead of oxygen is total thickness:

preferred because silane reaction with oxygen is spon-

taneous and oxide particles are produced everywhere WF 6 (g) + SiH 4 (g) −→

in the system and they float around in the reactor and W (s) + 2HF (g) + H 2 (g) + SiF 4 (g)

deposit sporadically on wafers.

CVD is not limited to simple compounds: films WF 6 (g) + 3H 2 (g) −→ W (s) + 6HF (g)

can be doped during deposition. CVD oxide can be

This process is able to fill holes and trenches and it is

doped by adding phosphine (PH 3 ) gas to the source

very important in multilevel metallization (Chapter 27).

gas flow. Phosphorus doped CVD oxide, also known as

phosphorus doped silica glass (PSG), is a widely used

doped film. Phosphorus oxide is formed by CVD and 5.5.1 CVD rate and mechanism

intermixed with silicon dioxide.

The two main differences between PVD and CVD reac-

tions are in flow dynamics and temperature dependence:

4PH 3 (g) + 5O 2 (g) −→ 2P 2 O 5 (s) + 6H 2 (g)

in PVD, fluid dynamics need not be considered, but

CVD processes are flow processes with complex fluid

Doped oxide films typically have ca. 5% by weight dynamics. In PVD processes, deposition rate depends

dopant. Higher doping levels lead to porous, hygro- primarily on target excitation energy. CVD processes

scopic material. Toxicity of PH 3 (and B 2 H 6 for BSG) are chemical processes, and their rates obey Arrhenius

needs to accounted for, but CVD reactors use silane, behaviour. The activation energy E a can be extracted

which is a flammable gas, so the basic designs of CVD from the Arrhenius formula when the deposition rate

reactors are suitable for dangerous gases. Trimethyl has been determined at several temperatures. The mag-

phosphite (TMP) and trimethyl borate (TMB) are less nitude of the activation energy gives hints to possible

toxic alternatives to hydrides. reaction mechanisms.

Phosphorus getters mobile ions like sodium and Two temperature regimes can be found for most CVD

potassium, and makes PSG a more efficient barrier reactions (Figure 5.6): when the temperature is low,

against the ambient than undoped CVD oxide (which the surface reaction rate is low, and there is an over-

is sometimes known as USG, for undoped silica abundance of reactants. The reaction is then in the sur-

glass). PSG etch rate is much faster than that of face reaction–limited regime. The rate of silicon nitride

◦

undoped oxide, and PSG is a popular sacrificial layer deposition from SiH 2 Cl 2 at 770 C is ca. 3.3 nm/min.

in micromechanics. This is compensated by the fact that deposition takes

CVD tungsten is deposited in two steps. The silane place on up to 100 wafers simultaneously.

reduction step deposits a thin nucleation layer over every When the temperature increases, the surface reaction

surface in the system, and high rate blanket deposition rate increases exponentially, and above a certain temper-

with hydrogen reduction is used to achieve the desired ature, all source gas molecules react at the surface. The