Page 89 - Sami Franssila Introduction to Microfabrication

P. 89

68 Introduction to Microfabrication

Figure 6.4 Terrace step kink (TSK) growth model of epitaxy: growth proceeds at kinks, and atoms on flat surface diffuse

to energetically favourable positions at kinks. Wafer miscut creates terraced structure

n +

p substrate

+

(a) (b)

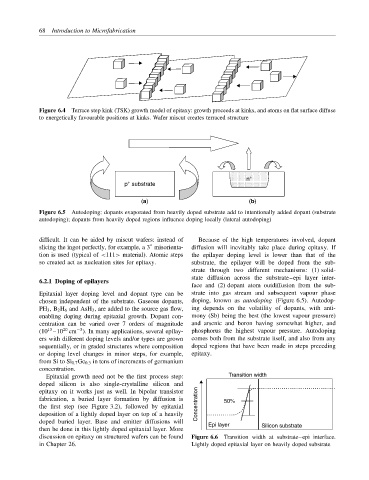

Figure 6.5 Autodoping: dopants evaporated from heavily doped substrate add to intentionally added dopant (substrate

autodoping); dopants from heavily doped regions influence doping locally (lateral autodoping)

difficult. It can be aided by miscut wafers: instead of Because of the high temperatures involved, dopant

◦

slicing the ingot perfectly, for example, a 3 misorienta- diffusion will inevitably take place during epitaxy. If

tion is used (typical of <111> material). Atomic steps the epilayer doping level is lower than that of the

so created act as nucleation sites for epitaxy. substrate, the epilayer will be doped from the sub-

strate through two different mechanisms: (1) solid-

state diffusion across the substrate–epi layer inter-

6.2.1 Doping of epilayers

face and (2) dopant atom outdiffusion from the sub-

Epitaxial layer doping level and dopant type can be strate into gas stream and subsequent vapour phase

chosen independent of the substrate. Gaseous dopants, doping, known as autodoping (Figure 6.5). Autodop-

PH 3 , B 2 H 6 and AsH 3 , are added to the source gas flow, ing depends on the volatility of dopants, with anti-

enabling doping during epitaxial growth. Dopant con- mony (Sb) being the best (the lowest vapour pressure)

centration can be varied over 7 orders of magnitude and arsenic and boron having somewhat higher, and

−3

20

13

(10 –10 cm ). In many applications, several epilay- phosphorus the highest vapour pressure. Autodoping

ers with different doping levels and/or types are grown comes both from the substrate itself, and also from any

sequentially, or in graded structures where composition doped regions that have been made in steps preceding

or doping level changes in minor steps, for example, epitaxy.

from Si to Si 0.7 Ge 0.3 in tens of increments of germanium

concentration.

Epitaxial growth need not be the first process step: Transition width

doped silicon is also single-crystalline silicon and

epitaxy on it works just as well. In bipolar transistor

fabrication, a buried layer formation by diffusion is 50%

the first step (see Figure 3.2), followed by epitaxial Concentration

deposition of a lightly doped layer on top of a heavily

doped buried layer. Base and emitter diffusions will Epi layer

then be done in this lightly doped epitaxial layer. More Silicon substrate

discussion on epitaxy on structured wafers can be found Figure 6.6 Transition width at substrate–epi interface.

in Chapter 26. Lightly doped epitaxial layer on heavily doped substrate