Page 187 - Lean six sigma demystified

P. 187

166 Lean Six Sigma DemystifieD

Fulfillment errors

30

25

UCL 19.84

20

UCL

+2 Sigma

+1 Sigma

Errors 15 Average

–1 Sigma

–2 Sigma

CL 10.24 LCL

10

7.05

5

2.40

L C L 6 . 0 4

0

2000–10 2000–12 2001–02 2001–04 2001–06 2001–08 2001–10 2001–12 2002–02 2002–04 2002–06 2002–08 2002–10 2002–11 2003–01 2003–03

2000-2003

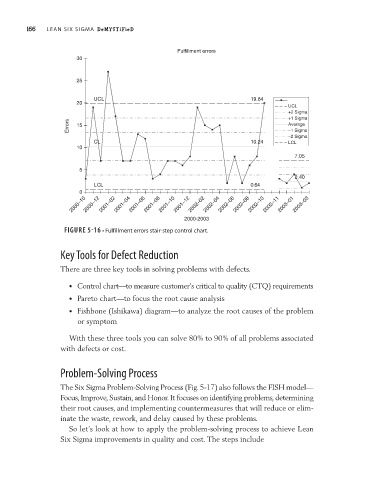

FIGURE 5-16 • Fulfillment errors stair-step control chart.

Key Tools for Defect Reduction

There are three key tools in solving problems with defects.

• Control chart—to measure customer’s critical to quality (CTQ) requirements

• Pareto chart—to focus the root cause analysis

• Fishbone (Ishikawa) diagram—to analyze the root causes of the problem

or symptom

With these three tools you can solve 80% to 90% of all problems associated

with defects or cost.

Problem-Solving Process

The Six Sigma Problem-Solving Process (Fig. 5-17) also follows the FISH model—

Focus, Improve, Sustain, and Honor. It focuses on identifying problems, determining

their root causes, and implementing countermeasures that will reduce or elim-

inate the waste, rework, and delay caused by these problems.

So let’s look at how to apply the problem-solving process to achieve Lean

Six Sigma improvements in quality and cost. The steps include