Page 147 - MEMS Mechanical Sensors

P. 147

136 Pressure Sensors

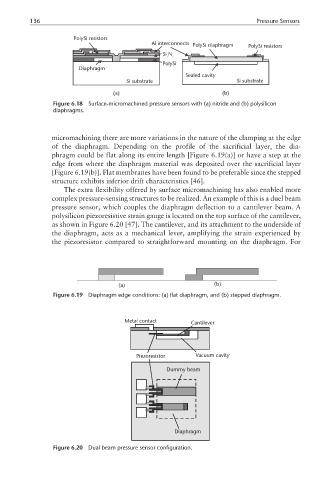

Figure 6.18 Surface-micromachined pressure sensors with (a) nitride and (b) polysilicon

diaphragms.

micromachining there are more variations in the nature of the clamping at the edge

of the diaphragm. Depending on the profile of the sacrificial layer, the dia-

phragm could be flat along its entire length [Figure 6.19(a)] or have a step at the

edge from where the diaphragm material was deposited over the sacrificial layer

[Figure 6.19(b)]. Flat membranes have been found to be preferable since the stepped

structure exhibits inferior drift characteristics [46].

The extra flexibility offered by surface micromachining has also enabled more

complex pressure-sensing structures to be realized. An example of this is a duel beam

pressure sensor, which couples the diaphragm deflection to a cantilever beam. A

polysilicon piezoresistive strain gauge is located on the top surface of the cantilever,

as shown in Figure 6.20 [47]. The cantilever, and its attachment to the underside of

the diaphragm, acts as a mechanical lever, amplifying the strain experienced by

the piezoresistor compared to straightforward mounting on the diaphragm. For

(a) (b)

Figure 6.19 Diaphragm edge conditions: (a) flat diaphragm, and (b) stepped diaphragm.

Metal contact Cantilever

Piezoresistor Vacuum cavity

Dummy beam

Diaphragm

Figure 6.20 Dual beam pressure sensor configuration.