Page 148 - MEMS Mechanical Sensors

P. 148

6.5 MEMS Technology Pressure Sensors 137

temperature compensation, a second beam with piezoresistor is positioned along-

side but not coupled to the diaphragm. The diaphragm is a polysilicon layer that

coats the entire chip surface (except bond pads), thereby physically, electrically, and

thermally isolating the strain gauges and beams from the pressurized media.

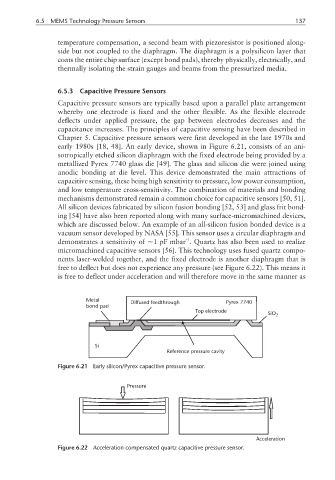

6.5.3 Capacitive Pressure Sensors

Capacitive pressure sensors are typically based upon a parallel plate arrangement

whereby one electrode is fixed and the other flexible. As the flexible electrode

deflects under applied pressure, the gap between electrodes decreases and the

capacitance increases. The principles of capacitive sensing have been described in

Chapter 5. Capacitive pressure sensors were first developed in the late 1970s and

early 1980s [18, 48]. An early device, shown in Figure 6.21, consists of an ani-

sotropically etched silicon diaphragm with the fixed electrode being provided by a

metallized Pyrex 7740 glass die [49]. The glass and silicon die were joined using

anodic bonding at die level. This device demonstrated the main attractions of

capacitive sensing, these being high sensitivity to pressure, low power consumption,

and low temperature cross-sensitivity. The combination of materials and bonding

mechanisms demonstrated remain a common choice for capacitive sensors [50, 51].

All silicon devices fabricated by silicon fusion bonding [52, 53] and glass frit bond-

ing [54] have also been reported along with many surface-micromachined devices,

which are discussed below. An example of an all-silicon fusion bonded device is a

vacuum sensor developed by NASA [55]. This sensor uses a circular diaphragm and

–1

demonstrates a sensitivity of ∼1 pF mbar . Quartz has also been used to realize

micromachined capacitive sensors [56]. This technology uses fused quartz compo-

nents laser-welded together, and the fixed electrode is another diaphragm that is

free to deflect but does not experience any pressure (see Figure 6.22). This means it

is free to deflect under acceleration and will therefore move in the same manner as

Figure 6.21 Early silicon/Pyrex capacitive pressure sensor.

Pressure

Acceleration

Figure 6.22 Acceleration compensated quartz capacitive pressure sensor.