Page 153 - MEMS Mechanical Sensors

P. 153

142 Pressure Sensors

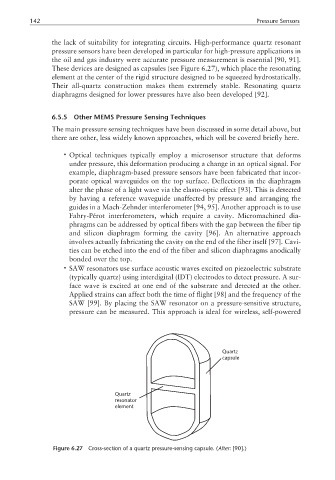

the lack of suitability for integrating circuits. High-performance quartz resonant

pressure sensors have been developed in particular for high-pressure applications in

the oil and gas industry were accurate pressure measurement is essential [90, 91].

These devices are designed as capsules (see Figure 6.27), which place the resonating

element at the center of the rigid structure designed to be squeezed hydrostatically.

Their all-quartz construction makes them extremely stable. Resonating quartz

diaphragms designed for lower pressures have also been developed [92].

6.5.5 Other MEMS Pressure Sensing Techniques

The main pressure sensing techniques have been discussed in some detail above, but

there are other, less widely known approaches, which will be covered briefly here.

• Optical techniques typically employ a microsensor structure that deforms

under pressure, this deformation producing a change in an optical signal. For

example, diaphragm-based pressure sensors have been fabricated that incor-

porate optical waveguides on the top surface. Deflections in the diaphragm

alter the phase of a light wave via the elasto-optic effect [93]. This is detected

by having a reference waveguide unaffected by pressure and arranging the

guides in a Mach-Zehnder interferometer [94, 95]. Another approach is to use

Fabry-Pérot interferometers, which require a cavity. Micromachined dia-

phragms can be addressed by optical fibers with the gap between the fiber tip

and silicon diaphragm forming the cavity [96]. An alternative approach

involves actually fabricating the cavity on the end of the fiber itself [97]. Cavi-

ties can be etched into the end of the fiber and silicon diaphragms anodically

bonded over the top.

• SAW resonators use surface acoustic waves excited on piezoelectric substrate

(typically quartz) using interdigital (IDT) electrodes to detect pressure. A sur-

face wave is excited at one end of the substrate and detected at the other.

Applied strains can affect both the time of flight [98] and the frequency of the

SAW [99]. By placing the SAW resonator on a pressure-sensitive structure,

pressure can be measured. This approach is ideal for wireless, self-powered

Figure 6.27 Cross-section of a quartz pressure-sensing capsule. (After: [90].)