Page 178 - MEMS Mechanical Sensors

P. 178

7.8 Tactile Sensors 167

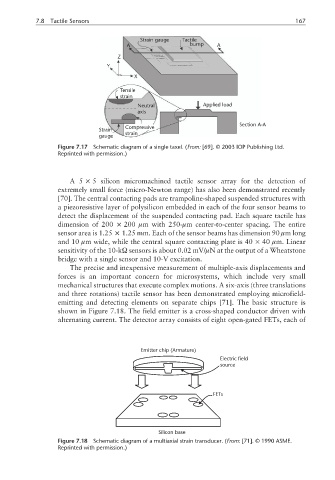

Figure 7.17 Schematic diagram of a single taxel. (From: [69]. © 2003 IOP Publishing Ltd.

Reprinted with permission.)

A5 × 5 silicon micromachined tactile sensor array for the detection of

extremely small force (micro-Newton range) has also been demonstrated recently

[70]. The central contacting pads are trampoline-shaped suspended structures with

a piezoresistive layer of polysilicon embedded in each of the four sensor beams to

detect the displacement of the suspended contacting pad. Each square tactile has

dimension of 200 × 200 µm with 250-µm center-to-center spacing. The entire

sensor area is 1.25 × 1.25 mm. Each of the sensor beams has dimension 90 µm long

and 10 µm wide, while the central square contacting plate is 40 × 40 µm. Linear

sensitivity of the 10-kΩ sensors is about 0.02 mV/µN at the output of a Wheatstone

bridge with a single sensor and 10-V excitation.

The precise and inexpensive measurement of multiple-axis displacements and

forces is an important concern for microsystems, which include very small

mechanical structures that execute complex motions. A six-axis (three translations

and three rotations) tactile sensor has been demonstrated employing microfield-

emitting and detecting elements on separate chips [71]. The basic structure is

shown in Figure 7.18. The field emitter is a cross-shaped conductor driven with

alternating current. The detector array consists of eight open-gated FETs, each of

Emitter chip (Armature)

Electric field

source

FETs

Silicon base

Figure 7.18 Schematic diagram of a multiaxial strain transducer. (From: [71]. © 1990 ASME.

Reprinted with permission.)