Page 216 - MEMS Mechanical Sensors

P. 216

8.3 Micromachined Gyroscopes 205

Voltage

multiplier

Velocity amp

Trim

and

test

Rate

Drivers sensor

Regulators

Coriolis

amp

Output

Demodulator Bias

References

Temperature

(a)

Inner frame

Resonating mass

Mass drive direction

Springs

Coriolis sense fingers

(b)

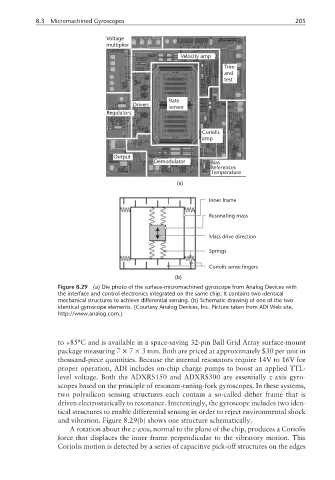

Figure 8.29 (a) Die photo of the surface-micromachined gyroscope from Analog Devices with

the interface and control electronics integrated on the same chip. It contains two identical

mechanical structures to achieve differential sensing. (b) Schematic drawing of one of the two

identical gyroscope elements. (Courtesy Analog Devices, Inc. Picture taken from ADI Web site,

http://www.analog.com.)

to +85°C and is available in a space-saving 32-pin Ball Grid Array surface-mount

package measuring 7 × 7 × 3 mm. Both are priced at approximately $30 per unit in

thousand-piece quantities. Because the internal resonators require 14V to 16V for

proper operation, ADI includes on-chip charge pumps to boost an applied TTL-

level voltage. Both the ADXRS150 and ADXRS300 are essentially z-axis gyro-

scopes based on the principle of resonant-tuning-fork gyroscopes. In these systems,

two polysilicon sensing structures each contain a so-called dither frame that is

driven electrostatically to resonance. Interestingly, the gyroscope includes two iden-

tical structures to enable differential sensing in order to reject environmental shock

and vibration. Figure 8.29(b) shows one structure schematically.

A rotation about the z-axis, normal to the plane of the chip, produces a Coriolis

force that displaces the inner frame perpendicular to the vibratory motion. This

Coriolis motion is detected by a series of capacitive pick-off structures on the edges