Page 231 - MEMS Mechanical Sensors

P. 231

220 Flow Sensors

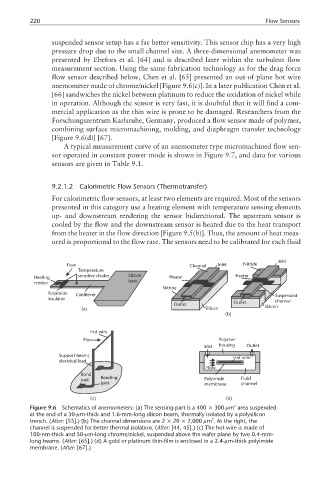

suspended sensor setup has a far better sensitivity. This sensor chip has a very high

pressure drop due to the small channel size. A three-dimensional anemometer was

presented by Ebefors et al. [64] and is described later within the turbulent flow

measurement section. Using the same fabrication technology as for the drag force

flow sensor described below, Chen et al. [65] presented an out-of-plane hot wire

anemometer made of chrome/nickel [Figure 9.6(c)]. In a later publication Chen et al.

[66] sandwiches the nickel between platinum to reduce the oxidation of nickel while

in operation. Although the sensor is very fast, it is doubtful that it will find a com-

mercial application as the thin wire is prone to be damaged. Researchers from the

Forschungszentrum Karlsruhe, Germany, produced a flow sensor made of polymer,

combining surface micromachining, molding, and diaphragm transfer technology

[Figure 9.6(d)] [67].

A typical measurement curve of an anemometer type micromachined flow sen-

sor operated in constant power mode is shown in Figure 9.7, and data for various

sensors are given in Table 9.1.

9.2.1.2 Calorimetric Flow Sensors (Thermotransfer)

For calorimetric flow sensors, at least two elements are required. Most of the sensors

presented in this category use a heating element with temperature sensing elements

up- and downstream rendering the sensor bidirectional. The upstream sensor is

cooled by the flow and the downstream sensor is heated due to the heat transport

from the heater in the flow direction [Figure 9.5(b)]. Thus, the amount of heat meas-

ured is proportional to the flow rate. The sensors need to be calibrated for each fluid

Inlet

Flow Channel Inlet Nitride

Temperature

Heating sensitive diodes Silicon Heater Heater

resistor base

Nitride

Polyimide Cantilever Suspended

insulator

Outlet channel

Outlet

(a) Silicon Silicon

(b)

Hot wire

Flow Polymer

Inlet housing Outlet

Support beam/ Hot wire

electrical lead

Flow

Bond

pad Bending Polyimide Fluid

joint membrane channel

(c) (d)

2

Figure 9.6 Schematics of anemometers: (a) The sensing part is a 400 × 300-µm area suspended

at the end of a 30-µm-thick and 1.6-mm-long silicon beam, thermally isolated by a polysilicon

3

trench. (After: [55].) (b) The channel dimensions are 2 × 20 × 2,000 µm . At the right, the

channel is suspended for better thermal isolation. (After: [44, 45].) (c) The hot wire is made of

100-nm-thick and 50-µm-long chrome/nickel, suspended above the wafer plane by two 0.4-mm-

long beams. (After: [65].) (d) A gold or platinum thin-film is enclosed in a 2.4-µm-thick polyimide

membrane. (After: [67].)