Page 232 - MEMS Mechanical Sensors

P. 232

9.2 Thermal Flow Sensors 221

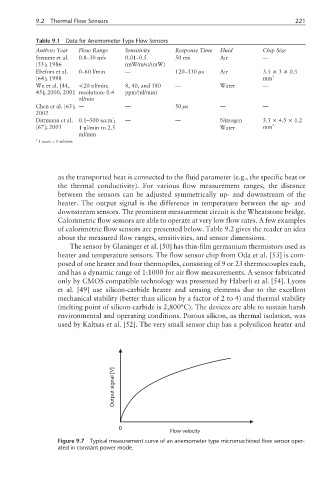

Table 9.1 Data for Anemometer Type Flow Sensors

Author; Year Flow Range Sensitivity Response Time Fluid Chip Size

Stemme et al. 0.8–30 m/s 0.01–0.5 50 ms Air —

[55]; 1986 (mW/m/s)/(mW)

Ebefors et al. 0–60 l/min — 120–330 µs Air 3.5 × 3 × 0.5

[64]; 1998 mm 3

Wu et al. [44, <20 nl/min; 8, 40, and 180 — Water —

45]; 2000, 2001 resolution: 0.4 ppm/(nl/min)

nl/min

Chen et al. [65]; — — 50 µs — —

2002

1

Dittmann et al. 0.1–500 sccm ; — — Nitrogen 5.5 × 4.5 × 1.2

[67]; 2001 1 µl/min to 2.5 Water mm 3

ml/min

1 sccm = 1 ml/min

1

as the transported heat is connected to the fluid parameter (e.g., the specific heat or

the thermal conductivity). For various flow measurement ranges, the distance

between the sensors can be adjusted symmetrically up- and downstream of the

heater. The output signal is the difference in temperature between the up- and

downstream sensors. The prominent measurement circuit is the Wheatstone bridge.

Calorimetric flow sensors are able to operate at very low flow rates. A few examples

of calorimetric flow sensors are presented below. Table 9.2 gives the reader an idea

about the measured flow ranges, sensitivities, and sensor dimensions.

The sensor by Glaninger et al. [50] has thin-film germanium thermistors used as

heater and temperature sensors. The flow sensor chip from Oda et al. [53] is com-

posed of one heater and four thermopiles, consisting of 9 or 23 thermocouples each,

and has a dynamic range of 1:1000 for air flow measurements. A sensor fabricated

only by CMOS compatible technology was presented by Häberli et al. [54]. Lyons

et al. [49] use silicon-carbide heater and sensing elements due to the excellent

mechanical stability (better than silicon by a factor of 2 to 4) and thermal stability

(melting point of silicon-carbide is 2,800°C). The devices are able to sustain harsh

environmental and operating conditions. Porous silicon, as thermal isolation, was

used by Kaltsas et al. [52]. The very small sensor chip has a polysilicon heater and

[V]

signal

Output

0

Flow velocity

Figure 9.7 Typical measurement curve of an anemometer type micromachined flow sensor oper-

ated in constant power mode.