Page 35 - MEMS Mechanical Sensors

P. 35

24 Materials and Fabrication Techniques

Table 2.5 Comparison of Commonly Used Silicon Anisotropic Etchants

Etchant Etches Aluminum Etches Oxide Silicon Surface Advantages Disadvantages

KOH Yes Yes Very good Easy to use and Etches aluminum

dispose of and oxide

EDP Yes (but some No Good Does not etch Hazardous,

formulations do oxide difficult to use, not

not etch aluminum) clean-room

compatible

TMAH Yes No Good Clean-room and IC Etches aluminum

process compatible

TMAH:Si No No Poor Does not etch Poor surface finish

aluminum

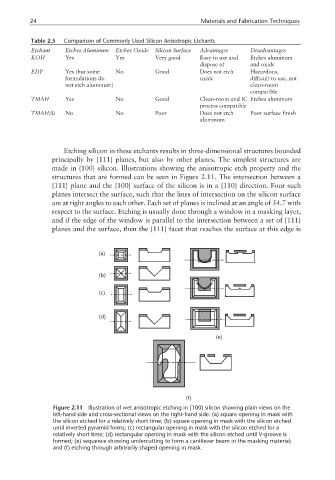

Etching silicon in these etchants results in three-dimensional structures bounded

principally by {111} planes, but also by other planes. The simplest structures are

made in {100} silicon. Illustrations showing the anisotropic etch property and the

structures that are formed can be seen in Figure 2.11. The intersection between a

{111} plane and the {100} surface of the silicon is in a {110} direction. Four such

planes intersect the surface, such that the lines of intersection on the silicon surface

are at right angles to each other. Each set of planes is inclined at an angle of 54.7 with

respect to the surface. Etching is usually done through a window in a masking layer,

and if the edge of the window is parallel to the intersection between a set of {111}

planes and the surface, then the {111} facet that reaches the surface at this edge is

(a)

(b)

(c)

(d)

(e)

(f)

Figure 2.11 Illustration of wet anisotropic etching in {100} silicon showing plain views on the

left-hand side and cross-sectional views on the right-hand side: (a) square opening in mask with

the silicon etched for a relatively short time; (b) square opening in mask with the silicon etched

until inverted pyramid forms; (c) rectangular opening in mask with the silicon etched for a

relatively short time; (d) rectangular opening in mask with the silicon etched until V-groove is

formed; (e) sequence showing undercutting to form a cantilever beam in the masking material;

and (f) etching through arbitrarily shaped opening in mask.