Page 47 -

P. 47

3-2 MEMS: Design and Fabrication

3.16 Surface Micromachining Processes ............................3-130

Basic Process Sequence • Fabrication Step Details • Control

of Film Stress • Dimensional Uncertainties • Sealing

Processes in Surface Micromachining • IC Compatibility

3.17 Poly-Si Surface Micromachining Modifications ......3-145

Porous Poly-Si • Hinged Polysilicon • Thick Polysilicon

• Milli-Scale Molded Polysilicon Structures

3.18 Surface Micromachining Modifications Not Involving

Polysilicon ....................................................................3-152

SOI Surface Micromachining • Resists as Structural

Elements and Molds in Surface Micromachining

3.19 Comparison of Bulk Micromachining with Surface

Micromachining ..........................................................3-161

3.20 Materials Case Studies ................................................3-163

Introduction • Polysilicon Deposition and Material Structure

• Amorphous and Hydrogenated Amorphous Silicon • Silicon

Nitride • CVD Silicon Dioxides • Metals in Surface

Guangyao Jia and Micromachining • Polycrystalline Diamond and SiC Films

Marc J. Madou 3.21 Polysilicon Surface Micromachining Examples ........3-181

University of California, Irvine

3.1 Wet Bulk Micromachining: Introduction

In wet bulk micromachining, features are sculpted in the bulk of materials such as silicon, quartz, SiC,

GaAs, InP, and Ge by orientation-independent (isotropic) or orientation-dependent (anisotropic) wet

etchants. The technology employs pools of liquid as tools [Harris, 1976] rather than dry etching plasmas.

A vast majority of wet bulk micromachining work is based on single-crystal silicon and glass as a com-

panion material. There has been some work on quartz, crystalline Ge, SiC, and GaAs, and a minor

amount on GaP and InP.

Wet bulk micromachining, along with surface micromachining, form the principal commercial Si

micromachining tool sets used today. Micromolding — from a lithography-defined master — has only

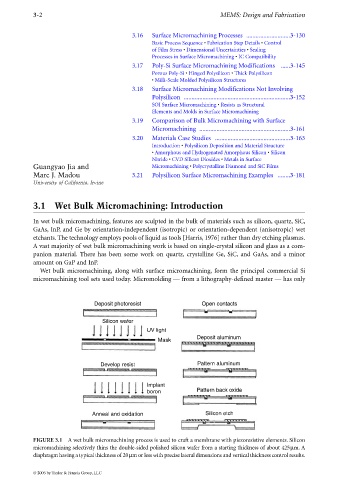

Deposit photoresist Open contacts

Silicon wafer

UV light

Deposit aluminum

Mask

Develop resist Pattern aluminum

Implant

boron Pattern back oxide

Anneal and oxidation Silicon etch

FIGURE 3.1 A wet bulk micromachining process is used to craft a membrane with piezoresistive elements. Silicon

micromachining selectively thins the double-sided polished silicon wafer from a starting thickness of about 425µm. A

diaphragm having a typical thickness of 20µm or less with precise lateral dimensions and vertical thickness control results.

© 2006 by Taylor & Francis Group, LLC