Page 53 -

P. 53

3-8 MEMS: Design and Fabrication

FIGURE 3.4 The diamond-type lattice can be constructed from two interpenetrating face-centered cubic unit cells.

Si forms four covalent bonds making tetrahedrons.

Primary Primary

flat flat

45°

Secondary

flat

[111] n-type [111] p-type

180°

Primary Primary

flat flat

90°

Secondary

flat Secondary

flat

[100] n-type [100] p-type

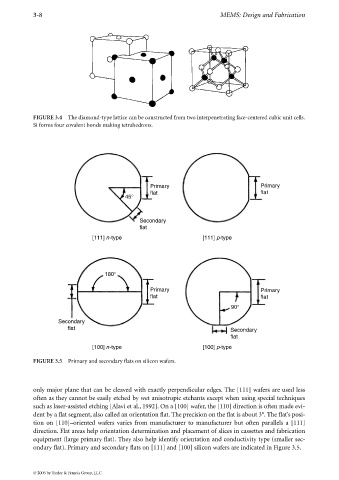

FIGURE 3.5 Primary and secondary flats on silicon wafers.

only major plane that can be cleaved with exactly perpendicular edges. The [111] wafers are used less

often as they cannot be easily etched by wet anisotropic etchants except when using special techniques

such as laser-assisted etching [Alavi et al., 1992]. On a [100] wafer, the [110] direction is often made evi-

dent by a flat segment, also called an orientation flat. The precision on the flat is about 3°. The flat’s posi-

tion on [110]–oriented wafers varies from manufacturer to manufacturer but often parallels a [111]

direction. Flat areas help orientation determination and placement of slices in cassettes and fabrication

equipment (large primary flat). They also help identify orientation and conductivity type (smaller sec-

ondary flat). Primary and secondary flats on [111] and [100] silicon wafers are indicated in Figure 3.5.

© 2006 by Taylor & Francis Group, LLC