Page 680 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 680

,

Arbor

Cutter

Spme Spindle Shank

End min

(a) Peripheral milling (b) e milling (c) End milling

(Ol) (9)

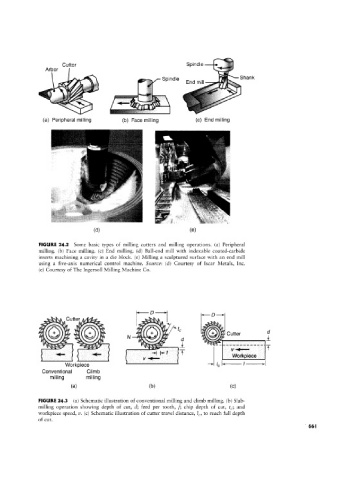

FIGURE 24.2 Some basic types of milling cutters and milling operations. la) Peripheral

milling. (b) Face milling. (c) End milling. (d) Ball-end mill with indexable coated-carbide

inserts machining a cavity in a die block. (e) Milling a sculptured surface with an end mill

using a five-axis numerical control machine. Source: (cl) Courtesy of Iscar Metals, Inc.

(e) Courtesy of The Ingersoll Milling Machine Co.

I ,_r;;~¢,

tsts

D

3 5/

A4Cutter ,

tsss

ii

_ig gi Toe] t I;

itawx/i,

‘Q

Y' ff ii; iyyiyy»s i & N 15 Cutter

d

/ii/wi e lm /w e' L i" ~-~-~-~-~----

+i iff T " ‘

V E Workpiece

/c l"“;' '“"’l

Workpieoe /

Conventional Climb

milling milling

(H) (bl (C)

FIGURE 24.3 (a) Schematic illustration of conventional milling and climb milling. (b) Slab-

milling operation showing depth of cut, d; feed per tooth, f; chip depth of cut, tc; and

workpiece speed, 1/_ (c) Schematic illustration of cutter travel distance, IC, to reach full depth

of cut.