Page 174 - Marks Calculation for Machine Design

P. 174

P1: Shibu

January 4, 2005

14:25

Brown.cls

Brown˙C04

STRENGTH OF MACHINES

156

interest. As with the uniaxial stress element, the four shear stresses (τ xy ) are zero. In the case

of a thin-walled spherical vessel under internal pressure, the normal stresses (σ sph ) in both

directions are equal. However, for either thin-walled or thick-walled cylinders, the normal

stresseswillbedifferent,andinfactthehooportangential stresswillbetwice theaxialstress.

The radial stress (σ r ) in a thick-walled cylinder acts perpendicular to the plane stress

element, in the z-direction, similar to that for an internal pressure (p i ), so it cannot be

depicted in Fig. 4.4.

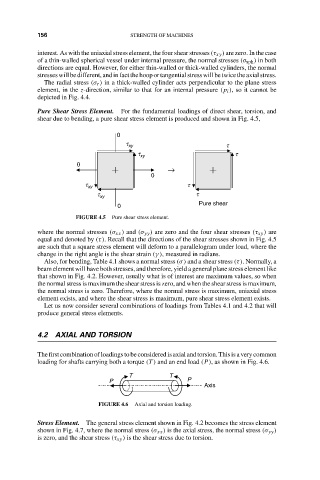

Pure Shear Stress Element. For the fundamental loadings of direct shear, torsion, and

shear due to bending, a pure shear stress element is produced and shown in Fig. 4.5,

0

t xy t

t xy t

0

→

0

t xy t

t xy t

0 Pure shear

FIGURE 4.5 Pure shear stress element.

where the normal stresses (σ xx ) and (σ yy ) are zero and the four shear stresses (τ xy ) are

equal and denoted by (τ). Recall that the directions of the shear stresses shown in Fig. 4.5

are such that a square stress element will deform to a parallelogram under load, where the

change in the right angle is the shear strain (γ ), measured in radians.

Also, for bending, Table 4.1 shows a normal stress (σ) and a shear stress (τ). Normally, a

beam element will have both stresses, and therefore, yield a general plane stress element like

that shown in Fig. 4.2. However, usually what is of interest are maximum values, so when

the normal stress is maximum the shear stress is zero, and when the shear stress is maximum,

the normal stress is zero. Therefore, where the normal stress is maximum, uniaxial stress

element exists, and where the shear stress is maximum, pure shear stress element exists.

Let us now consider several combinations of loadings from Tables 4.1 and 4.2 that will

produce general stress elements.

4.2 AXIAL AND TORSION

Thefirstcombinationofloadingstobeconsideredisaxialandtorsion.Thisisaverycommon

loading for shafts carrying both a torque (T ) and an end load (P), as shown in Fig. 4.6.

T T

P P

Axis

FIGURE 4.6 Axial and torsion loading.

Stress Element. The general stress element shown in Fig. 4.2 becomes the stress element

shown in Fig. 4.7, where the normal stress (σ xx ) is the axial stress, the normal stress (σ yy )

is zero, and the shear stress (τ xy ) is the shear stress due to torsion.