Page 209 - Marks Calculation for Machine Design

P. 209

P1: Shibu/Sanjay

14:35

January 4, 2005

Brown˙C05

Brown.cls

191

PRINCIPAL STRESSES AND MOHR’S CIRCLE

The angle (θ) in Fig. 5.3 is the weld angle and it is the stresses relative to this angle

that are most important to the design engineer. However, it is the stresses relative to the

natural axis of the cylinder that are found first, using the equations presented in Sec. 3.1.1.

Then Eqs. (5.1) to (5.3) are used to find the stresses along the direction defined by the

angle (θ).

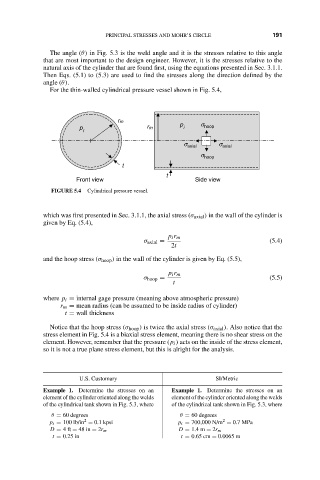

For the thin-walled cylindrical pressure vessel shown in Fig. 5.4,

rm

p s

p rm i hoop

i

s axial s axial

s hoop

t

t

Front view Side view

FIGURE 5.4 Cylindrical pressure vessel.

which was first presented in Sec. 3.1.1, the axial stress (σ axial ) in the wall of the cylinder is

given by Eq. (5.4),

p i r m

σ axial = (5.4)

2t

and the hoop stress (σ hoop ) in the wall of the cylinder is given by Eq. (5.5),

p i r m

σ hoop = (5.5)

t

where p i = internal gage pressure (meaning above atmospheric pressure)

r m = mean radius (can be assumed to be inside radius of cylinder)

t = wall thickness

Notice that the hoop stress (σ hoop ) is twice the axial stress (σ axial ). Also notice that the

stress element in Fig. 5.4 is a biaxial stress element, meaning there is no shear stress on the

element. However, remember that the pressure (p i ) acts on the inside of the stress element,

so it is not a true plane stress element, but this is alright for the analysis.

U.S. Customary SI/Metric

Example 1. Determine the stresses on an Example 1. Determine the stresses on an

element of the cylinder oriented along the welds element of the cylinder oriented along the welds

of the cylindrical tank shown in Fig. 5.3, where of the cylindrical tank shown in Fig. 5.3, where

θ = 60 degrees θ = 60 degrees

2

2

p i = 100 lb/in = 0.1 kpsi p i = 700,000 N/m = 0.7 MPa

D = 4ft = 48 in = 2r m D = 1.4 m = 2r m

t = 0.25 in t = 0.65 cm = 0.0065 m