Page 206 - Marks Calculation for Machine Design

P. 206

P1: Shibu

January 4, 2005

Brown˙C04

Brown.cls

188

U.S. Customary 14:25 STRENGTH OF MACHINES SI/Metric

Step 4. Using the maximum bending moment Step 4. Using the maximum bending moment

(M max ) found in step 3 calculate the maximum (M max ) found in step 3 calculate the maximum

bending stress (σ max ) from Eq. (4.37). bending stress (σ max ) from Eq. (4.37).

M max M max

σ max = σ max =

2

2

π r t π r t

m

m

(129,000 lb · ft)(12 in/ft) (194,000 N · m)

= =

2

2

π(36 in) (0.5in) π(1m) (0.013 m)

1,548,000 lb · in 194,000 N · m

= =

2036 in 3 0.0408 m 3

2

2

= 760 lb/in = 0.8 kpsi = 4,750,000 N/m = 4.8MPa

Step 5. Combine the axial stress (σ axial ) found Step 5. Combine the axial stress (σ axial ) found

in step 1 with the maximum bending stress in step 1 with the maximum bending stress

(σ max ) found in step 4 to give a maximum nor- (σ max ) found in step 4 to give a maximum nor-

mal stress (σ xx ). mal stress (σ xx )

σ xx = σ axial + σ max σ xx = σ axial + σ max

= (7.2 kpsi) + (0.8 kpsi) = (53.8 kpsi) + (4.8 kpsi)

= 8.0 kpsi = 58.6 kpsi

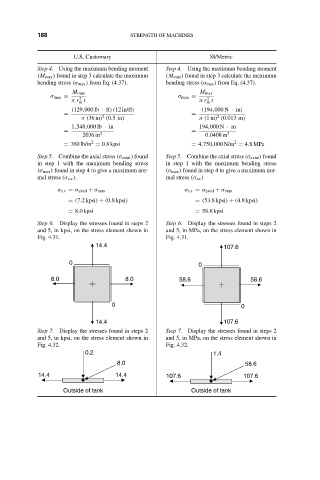

Step 6. Display the stresses found in steps 2 Step 6. Display the stresses found in steps 2

and 5, in kpsi, on the stress element shown in and 5, in MPa, on the stress element shown in

Fig. 4.31. Fig. 4.31.

14.4 107.6

0 0

8.0 8.0 58.6 58.6

0 0

14.4 107.6

Step 7. Display the stresses found in steps 2 Step 7. Display the stresses found in steps 2

and 5, in kpsi, on the stress element shown in and 5, in MPa, on the stress element shown in

Fig. 4.32. Fig. 4.32.

0.2 1.4

8.0 58.6

14.4 14.4 107.6 107.6

Outside of tank Outside of tank