Page 220 - Marks Calculation for Machine Design

P. 220

P1: Shibu/Sanjay

January 4, 2005

14:35

Brown.cls

Brown˙C05

STRENGTH OF MACHINES

202

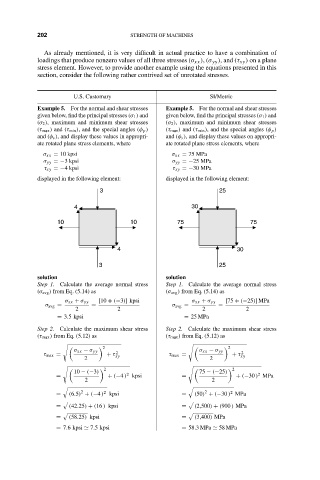

As already mentioned, it is very difficult in actual practice to have a combination of

loadings that produce nonzero values of all three stresses (σ xx ),(σ yy ), and (τ xy ) on a plane

stress element. However, to provide another example using the equations presented in this

section, consider the following rather contrived set of unrotated stresses.

U.S. Customary SI/Metric

Example 5. For the normal and shear stresses Example 5. For the normal and shear stresses

given below, find the principal stresses (σ 1 ) and given below, find the principal stresses (σ 1 ) and

(σ 2 ), maximum and minimum shear stresses (σ 2 ), maximum and minimum shear stresses

(τ max ) and (τ min ), and the special angles (φ p ) (τ max ) and (τ min ), and the special angles (φ p )

and (φ s ), and display these values in appropri- and (φ s ), and display these values on appropri-

ate rotated plane stress elements, where ate rotated plane stress elements, where

σ xx = 10 kpsi σ xx = 75 MPa

σ yy =−3 kpsi σ yy =−25 MPa

τ xy =−4 kpsi τ xy =−30 MPa

displayed in the following element: displayed in the following element:

3 25

4 30

10 10 75 75

4 30

3 25

solution solution

Step 1. Calculate the average normal stress Step 1. Calculate the average normal stress

(σ avg ) from Eq. (5.14) as (σ avg ) from Eq. (5.14) as

σ xx + σ yy [10 + (−3)] kpsi σ xx + σ yy [75 + (−25)]MPa

σ avg = = σ avg = =

2 2 2 2

= 3.5 kpsi = 25 MPa

Step 2. Calculate the maximum shear stress Step 2. Calculate the maximum shear stress

(τ max ) from Eq. (5.12) as (τ max ) from Eq. (5.12) as

2 2

σ xx − σ yy 2 σ xx − σ yy 2

τ max = + τ xy τ max = + τ xy

2 2

2 2

10 − (−3) 75 − (−25)

2

2

= + (−4 ) kpsi = + (−30 ) MPa

2 2

2

2

2

2

= (6.5) + (−4 ) kpsi = (50) + (−30 ) MPa

= (42.25) + (16 ) kpsi = (2,500) + (900 ) MPa

= (58.25) kpsi = (3,400) MPa

= 7.6 kpsi 7.5 kpsi = 58.3MPa 58 MPa