Page 271 - Marks Calculation for Machine Design

P. 271

P1: Shibu

January 4, 2005

14:56

Brown.cls

Brown˙C06

STATIC DESIGN AND COLUMN BUCKLING

Biaxial where 253

s = s > 0

2

1

s 2

Boundary of allowable

combinations 3

30

Biaxial where

2 s 1 = 2s > 0

2

s

–90 30 1

1

–30 Uniaxial where

4 s > 0, s = 0

1

2

5

Pure shear where

–90 s > 0, s = –s 1

1

2

Scale: 5 kpsi ¥ 5 kpsi

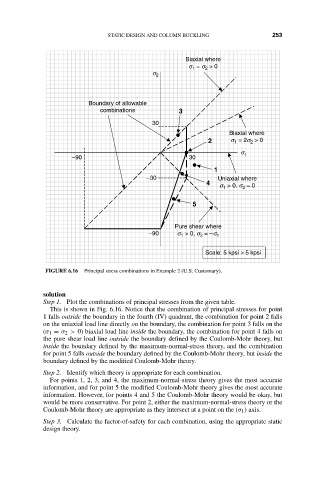

FIGURE 6.16 Principal stress combinations in Example 2 (U.S. Customary).

solution

Step 1. Plot the combinations of principal stresses from the given table.

This is shown in Fig. 6.16. Notice that the combination of principal stresses for point

1 falls outside the boundary in the fourth (IV) quadrant, the combination for point 2 falls

on the uniaxial load line directly on the boundary, the combination for point 3 falls on the

(σ 1 = σ 2 > 0) biaxial load line inside the boundary, the combination for point 4 falls on

the pure shear load line outside the boundary defined by the Coulomb-Mohr theory, but

inside the boundary defined by the maximum-normal-stress theory, and the combination

for point 5 falls outside the boundary defined by the Coulomb-Mohr theory, but inside the

boundary defined by the modified Coulomb-Mohr theory.

Step 2. Identify which theory is appropriate for each combination.

For points 1, 2, 3, and 4, the maximum-normal-stress theory gives the most accurate

information, and for point 5 the modified Coulomb-Mohr theory gives the most accurate

information. However, for points 4 and 5 the Coulomb-Mohr theory would be okay, but

would be more conservative. For point 2, either the maximum-normal-stress theory or the

Coulomb-Mohr theory are appropriate as they intersect at a point on the (σ 1 ) axis.

Step 3. Calculate the factor-of-safety for each combination, using the appropriate static

design theory.