Page 124 - Mechanical design of microresonators _ modeling and applications

P. 124

0-07-145538-8_CH03_123_08/30/05

Microhinges and Microcantilevers: Lumped-Parameter Modeling and Design

Microhinges and Microcantilevers: Lumped-Parameter Modeling and Design 123

6

2

rkb

0

0.1

c1

cw

0.2

0.9

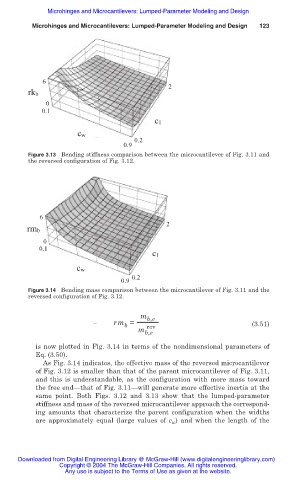

Figure 3.13 Bending stiffness comparison between the microcantilever of Fig. 3.11 and

the reversed configuration of Fig. 3.12.

UPE

F

FZ

Figure 3.14 Bending mass comparison between the microcantilever of Fig. 3.11 and the

reversed configuration of Fig. 3.12.

m b,e

rm = (3.51)

b

m rev

b,e

is now plotted in Fig. 3.14 in terms of the nondimensional parameters of

Eq. (3.50).

As Fig. 3.14 indicates, the effective mass of the reversed microcantilever

of Fig. 3.12 is smaller than that of the parent microcantilever of Fig. 3.11,

and this is understandable, as the configuration with more mass toward

the free end—that of Fig. 3.11—will generate more effective inertia at the

same point. Both Figs. 3.12 and 3.13 show that the lumped-parameter

stiffness and mass of the reversed microcantilever approach the correspond-

ing amounts that characterize the parent configuration when the widths

are approximately equal (large values of c w ) and when the length of the

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.