Page 262 - Mechanical design of microresonators _ modeling and applications

P. 262

0-07-145538-8_CH05_261_08/30/05

Resonant Micromechanical Systems

Resonant Micromechanical Systems 261

fishhook spring

anchor

y

x

Figure 5.37 Proof mass with fishhook microsuspension.

y

x anchor

bent-beam

serpentine spring

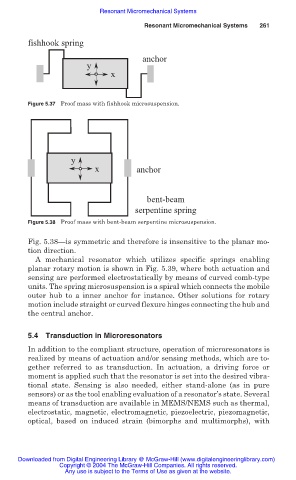

Figure 5.38 Proof mass with bent-beam serpentine microsuspension.

Fig. 5.38—is symmetric and therefore is insensitive to the planar mo-

tion direction.

A mechanical resonator which utilizes specific springs enabling

planar rotary motion is shown in Fig. 5.39, where both actuation and

sensing are performed electrostatically by means of curved comb-type

units. The spring microsuspension is a spiral which connects the mobile

outer hub to a inner anchor for instance. Other solutions for rotary

motion include straight or curved flexure hinges connecting the hub and

the central anchor.

5.4 Transduction in Microresonators

In addition to the compliant structure, operation of microresonators is

realized by means of actuation and/or sensing methods, which are to-

gether referred to as transduction. In actuation, a driving force or

moment is applied such that the resonator is set into the desired vibra-

tional state. Sensing is also needed, either stand-alone (as in pure

sensors) or as the tool enabling evaluation of a resonator’s state. Several

means of transduction are available in MEMS/NEMS such as thermal,

electrostatic, magnetic, electromagnetic, piezoelectric, piezomagnetic,

optical, based on induced strain (bimorphs and multimorphs), with

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.